Laser Printer Maintenance Kits Explained (Without the Tech Jargon)

A laser printer maintenance kit is a collection of replacement parts designed to refresh worn components and maintain consistent print quality in laser printers. Think of it as a scheduled tune-up that prevents unexpected breakdowns and extends your printer’s lifespan.

Quick Answer: Laser Printer Maintenance Kit Essentials

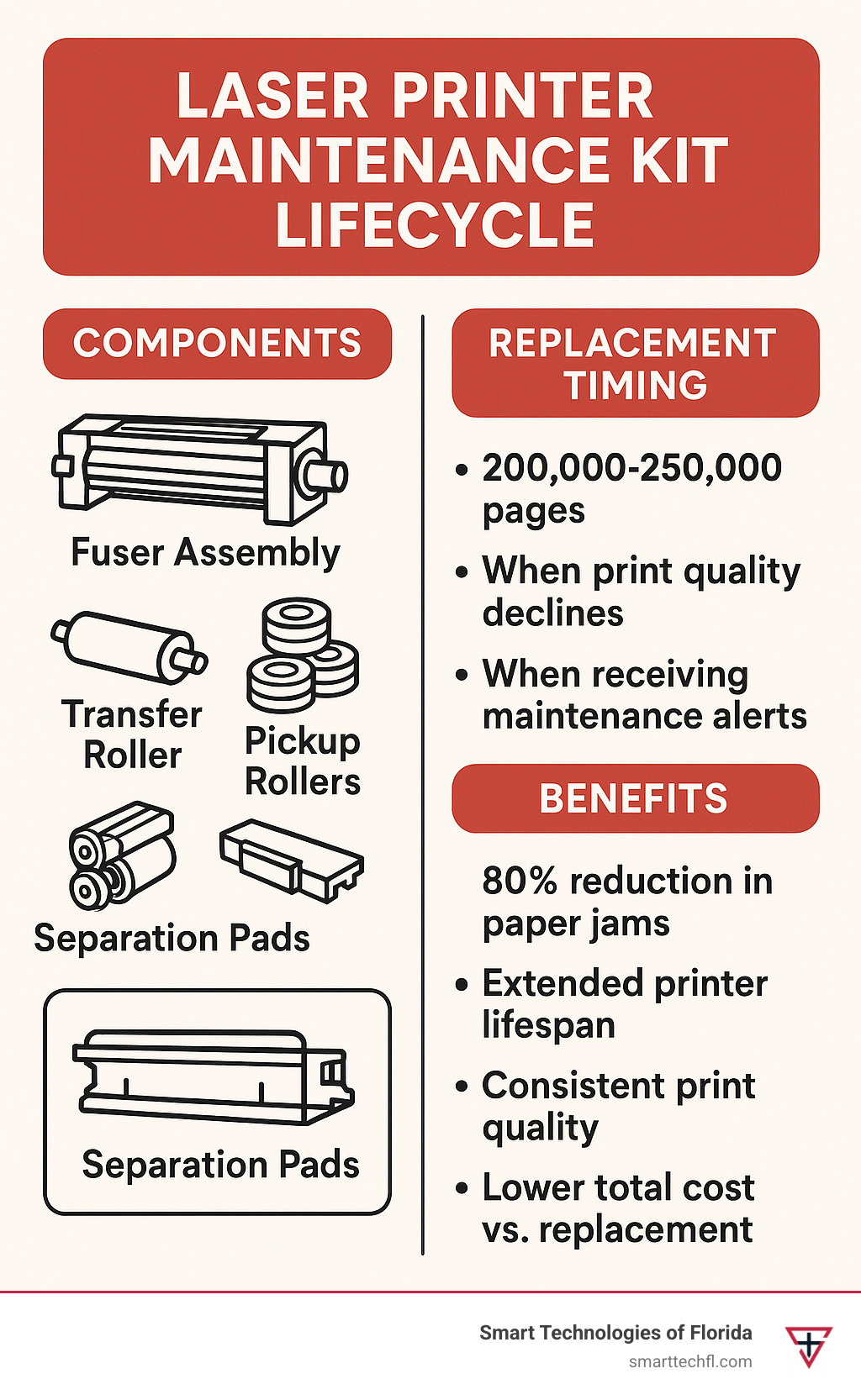

| What Is It? | When To Replace | What’s Included | Benefits |

|---|---|---|---|

| Collection of replacement parts for worn printer components | Every 200,000-250,000 pages (or when print quality declines) | Fuser assembly, transfer roller, pickup rollers, separation pads | Prevents paper jams, maintains print quality, extends printer life, reduces costs |

As one IT manager on a forum aptly put it: “Throwing away a printer that just needs a maintenance kit is like scrapping a car because it needs a transmission repair.” This preventative maintenance approach makes financial sense for businesses that rely on their printers daily.

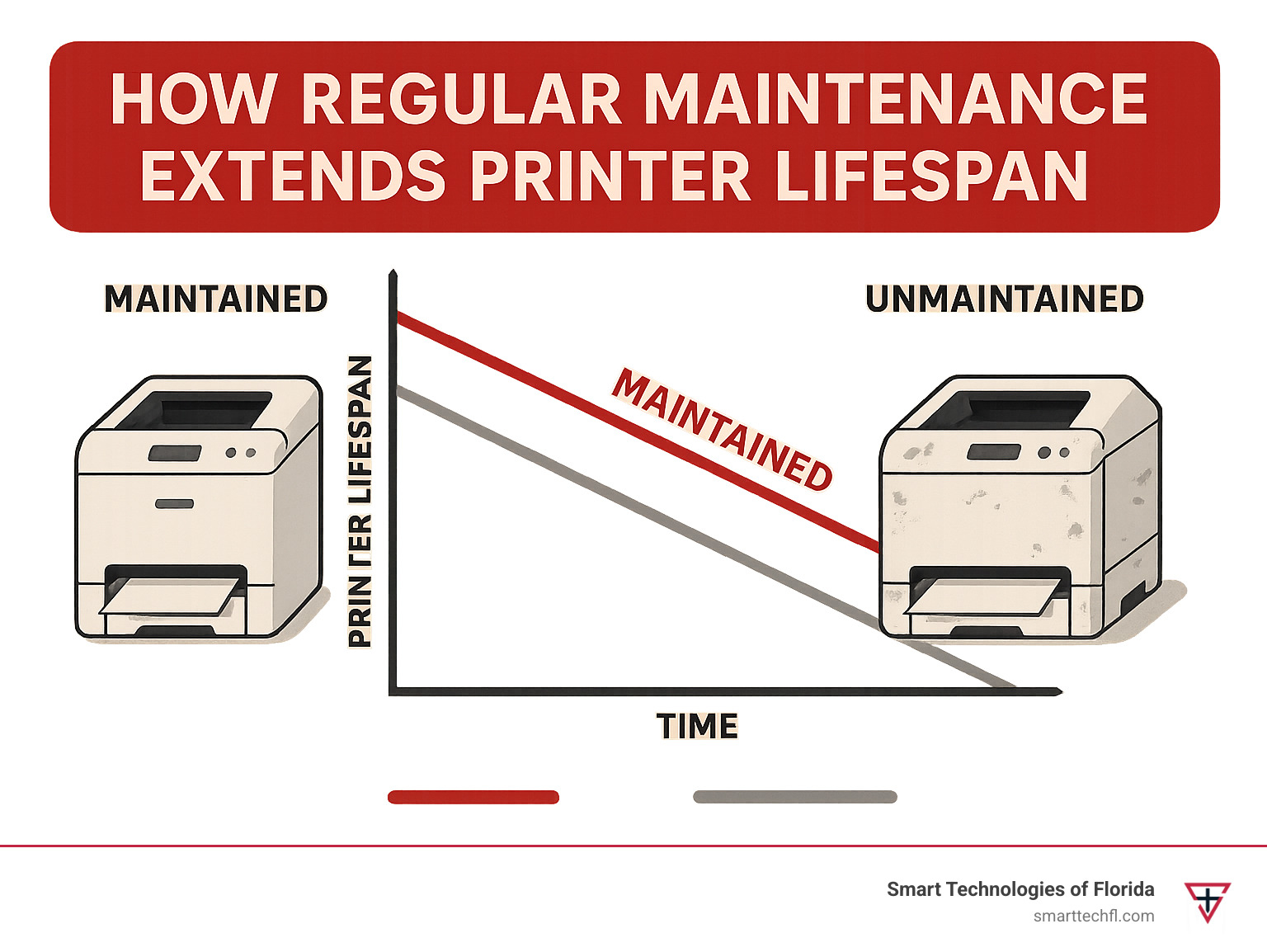

Laser printer maintenance kits typically cost between 35% and 50% of a new printer’s price but can extend your device’s lifespan by several years. Some businesses report printers lasting over 2 million pages through 5-6 maintenance cycles—making kits a smart investment for operational efficiency.

For retail businesses looking to control costs while maintaining productivity, understanding these kits is essential. Regular maintenance using these kits can reduce paper jams and misfeeds by up to 80%, according to manufacturer reports, keeping your operations running smoothly when you need them most.

Understanding the Laser Printer Maintenance Kit Basics

Laser printers are workhorses in most office environments, but like any mechanical device, they have components that wear out over time. Despite advances in technology, even The New Yorker has noted that paper jams will persist as an inevitable challenge—largely due to the physical nature of paper handling components that gradually wear down.

What Is a “laser printer maintenance kit”?

Think of a laser printer maintenance kit as a carefully curated care package for your hardworking printer. It’s not just random parts thrown together—it’s a thoughtfully designed collection of components that typically wear out after thousands of printed pages.

These kits aren’t created on a whim. Manufacturers analyze extensive data from millions of printers to determine exactly which parts need replacement after your printer reaches certain milestones in its duty cycle. Unlike toner cartridges that you replace regularly, these kits address the deeper mechanical components that silently keep your printer running smoothly day after day.

In our 23 years at Smart Technologies of Florida, we’ve seen printers transform from temperamental paper-jammers back to reliable workhorses after a proper maintenance kit installation. There’s something satisfying about giving a printer a second life with the right care. For more details on what’s inside these magical kits, check out our Laser Printer Maintenance Kit Contents Guide.

Why Your Printer Needs One

Your laser printer leads a surprisingly intense life. Did you know the fuser assembly regularly heats up to over 200°C (392°F)? That’s hotter than most home ovens when baking cookies! This extreme heat, combined with the constant friction of paper being pulled, pushed, and pressed through the machine, creates inevitable wear on multiple components.

A laser printer maintenance kit isn’t just a nice-to-have—it’s essential for keeping your business running smoothly. When worn components break completely, they often damage other parts in a domino effect of printer problems. We’ve seen businesses lose days of productivity waiting for replacement printers when a simple maintenance kit could have prevented the breakdown entirely.

Print quality suffers tremendously as rollers wear down. They gradually lose their grip on paper and their ability to transfer toner properly, resulting in those frustrating smudges, streaks, and faded text that make your professional documents look amateur. And those maddening paper jams? Up to 80% can be prevented with proper maintenance.

“I was about to throw our department’s printer out the window after weeks of constant paper jams,” one of our Daytona Beach clients told us with a laugh. “After installing a maintenance kit, it’s been running like new for over a year now. Wish I’d done it sooner!”

The beauty of regular maintenance is that it extends your printer’s lifespan dramatically. We’ve seen printers handle millions of pages rather than hundreds of thousands when properly maintained. That’s real money saved for your business, not to mention the environmental benefit of keeping perfectly good equipment out of landfills. For businesses looking to maximize their printer investments, proper maintenance isn’t just smart—it’s essential.

When & How to Know It’s Time for a Kit

Knowing when to replace your laser printer maintenance kit isn’t rocket science—it’s about paying attention to the signals your trusty office companion is sending your way.

Tell-Tale Signs Your Laser Printer Maintenance Kit Is Due

Your printer has its own way of crying for help before things go south. Think of these signs as your printer’s version of a check engine light:

Most modern printers will flash warning messages like “Perform Printer Maintenance” or “Replace Maintenance Kit” when their internal odometer hits certain milestones. But even without explicit warnings, your prints will tell the story.

Are your documents coming out looking faded or ghostly? That’s likely a worn transfer roller waving the white flag. Noticing smudged prints where toner wipes off with a gentle touch? Your fuser assembly is probably ready for retirement. Those annoying streaks or lines appearing on every page aren’t random—they’re your printer’s components asking for fresh replacements.

Paper handling issues are another dead giveaway. When you’re rescuing papers from the same jam spot for the third time this week, or noticing multiple sheets feeding simultaneously, your printer’s separation pads are likely worn smooth. And if your documents are coming out wrinkled like they’ve been stuffed in a pocket, that’s the fuser’s way of saying goodbye.

Even your ears can help diagnose maintenance needs. New grinding, squeaking, or scraping sounds during printing aren’t just annoying—they’re mechanical components in distress. And if your once-speedy printer now seems to operate in slow motion, it’s likely compensating for aging parts.

For the more technically inclined, you can check your printer’s current page count through the configuration page (usually accessible through the control panel menu) and compare it with the manufacturer’s recommended maintenance schedule. We’ve put together a comprehensive Laser Printer Maintenance Checklist Tips guide to help you stay on top of these warning signs.

Page Counts & Replacement Schedules

Laser printer maintenance kits are designed with specific page counts in mind, varying by printer class:

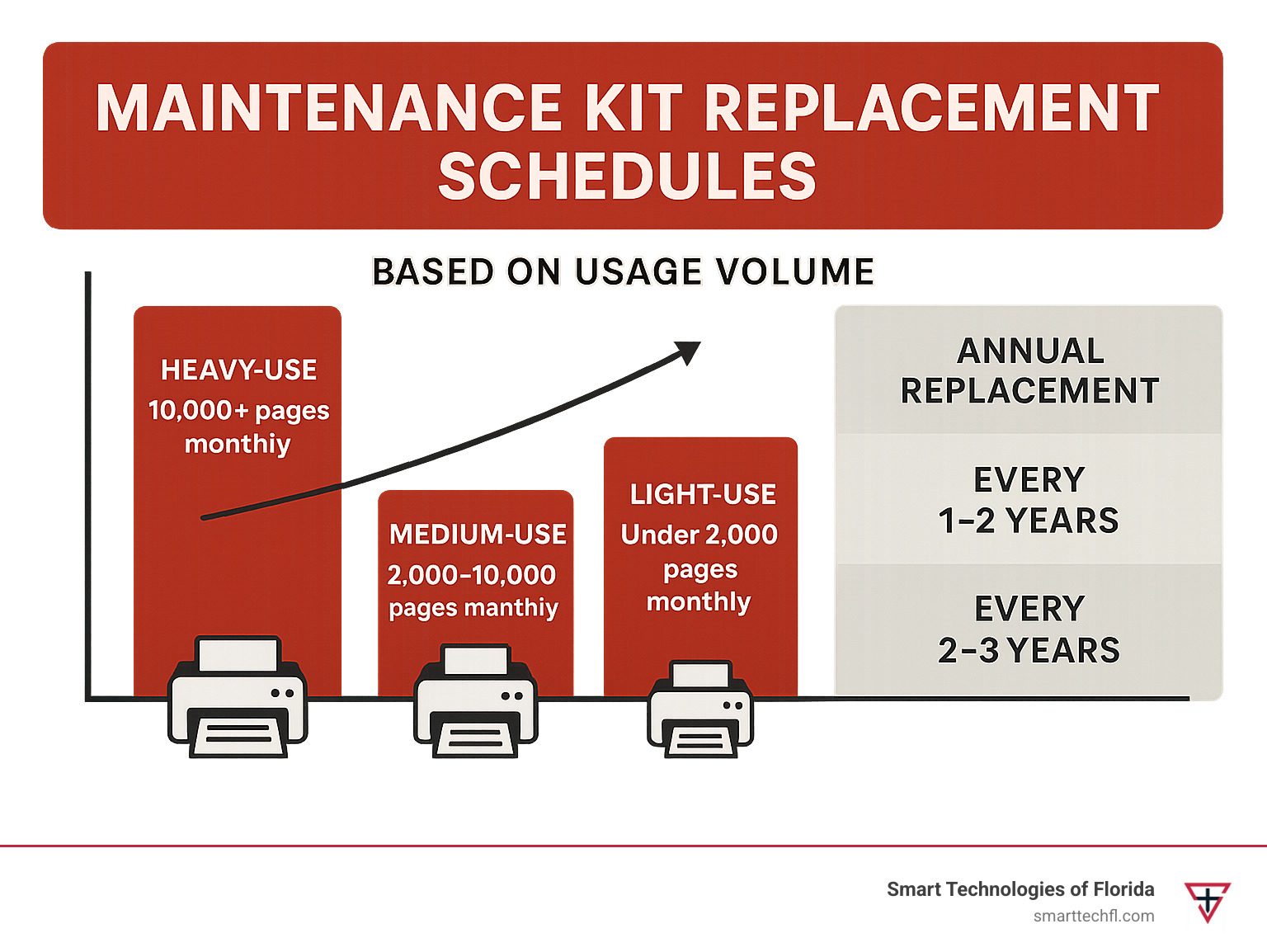

Enterprise-level workhorses typically need maintenance every 200,000 to 250,000 pages, while mid-range office printers usually require attention between 100,000 and 200,000 pages. Smaller business printers often need maintenance kits after 50,000 to 100,000 pages.

What does this mean in real-world terms? If your office is churning out over 10,000 pages monthly, plan for annual maintenance kit replacements. Medium-volume environments (2,000-10,000 monthly pages) can typically go 1-2 years between kits. Light users printing under 2,000 pages monthly might stretch to 2-3 years before replacement.

Here in Florida, we’ve noticed environmental factors play a significant role too. Printers near our coastal areas in Daytona Beach often need more frequent maintenance due to humidity affecting paper. Meanwhile, dustier environments can shorten component life as particles find their way into delicate mechanisms.

These are guidelines rather than strict rules. Your printer’s specific needs may vary based on usage patterns, paper types, and environmental conditions. When in doubt, those warning signs we discussed earlier will help you make the call—your printer knows when it’s time for some TLC.

Choosing the Right Kit: Compatibility, Voltage & OEM vs Third-Party

Finding the perfect laser printer maintenance kit feels a bit like matchmaking sometimes. After helping Florida businesses keep their printers happy for over two decades, we’ve learned that compatibility is everything—the wrong kit can lead to heartbreak (and wasted money).

Finding the Exact Kit for Your Printer Model

Your printer has a unique identity, and finding it is your first step. Think of it as your printer’s “name tag” that ensures you get exactly what it needs:

“I once had a client who ordered three expensive maintenance kits for the wrong model,” shares one of our technicians. “That’s a $600 mistake we helped them avoid the next time around.”

You can find your printer’s model number through several easy methods:

Look for a label on the front panel, back panel, or inside the front cover. Most manufacturers make this fairly obvious once you know where to look. Alternatively, steer through your printer’s control panel menu to the “Information” or “About” section, or print a configuration page directly from the printer’s menu system.

Once armed with your model number, finding the right kit becomes simple. Manufacturer websites typically offer lookup tools where you enter your model number for perfect matches. For HP printers, popular maintenance kits include the J8J87A (Enterprise 600 series) and CF249A (LaserJet Pro 400 series).

For a deeper dive into what these kits contain, check out our Laser Printer Maintenance Kit Contents Guide.

110V vs 220V Maintenance Kits

Here’s something many people overlook until it’s too late: voltage matters tremendously. The fuser in your maintenance kit needs to match your country’s electrical system.

Voltage mismatch can be dangerous. We had a client who purchased a European 220V kit for their Florida office running on 110V power. The fuser couldn’t reach proper temperature, resulting in toner that smudged off pages and eventually a costly repair.

North America uses 110-120V systems, while Europe, Asia, and many other regions use 220-240V systems. Installing the wrong voltage kit can lead to poor print quality, overheating risks, or even fire hazards in extreme cases.

The good news? Voltage information is clearly marked on kit packaging and in product descriptions. Just take that extra moment to verify before ordering.

OEM vs Third-Party: Pros & Cons

The eternal debate: original manufacturer parts or third-party alternatives? This choice often comes down to your specific needs and budget considerations.

OEM kits come directly from your printer’s manufacturer. They offer peace of mind with guaranteed compatibility, higher quality components tested to exact specifications, and usually include warranty coverage. The technical support available if issues arise is also valuable for many businesses. The downside? They typically cost 30-50% more than alternatives.

Third-party kits can offer significant savings—often 30-50% less than OEM options. Some businesses find this compelling, especially for older printer models where OEM kits might be harder to find. However, quality can vary significantly between suppliers, and using them might void your printer warranty if damage occurs.

“We’ve seen businesses go back and forth on this decision,” notes our service manager. “Most of our clients who depend heavily on their printers daily find that OEM kits provide better long-term value despite the higher initial cost.”

For a complete breakdown of what maintenance will cost you, our Laser Printer Maintenance Costs Explained guide offers transparent information to help make your decision easier.

Whatever you choose, regular maintenance is always more cost-effective than printer replacement. A well-maintained printer with quality parts can serve your business faithfully for many years to come.

Installing Your Laser Printer Maintenance Kit (Step-by-Step)

With the right approach, installing a laser printer maintenance kit can be a refreshing experience that gives your printer a second life. While I’ve guided countless Florida businesses through this process, I know it can seem intimidating at first. Let’s break it down into manageable steps that anyone can follow.

Preparation & Safety First

Before diving in, let’s make sure you’re set up for success. Your printer’s fuser gets hotter than a Florida sidewalk in August—about 200°C/392°F—so safety comes first!

Start by powering down your printer properly and unplugging it from the wall. Then give it at least 30 minutes to cool down—trust me, those fusers can cause nasty burns if you’re impatient.

While you’re waiting, create a clean workspace where you can spread out. I like to cover the surface with some old newspapers or scrap paper to catch any toner that might escape (and it always finds a way!). Keep a trash bag handy for the old parts, and gather your supplies: disposable gloves, anti-static wrist strap if you have one, a small container for screws, and some isopropyl alcohol with lint-free cloths.

One tip I always share with our clients: print a configuration page before you start. This gives you a record of your page counts and settings that might come in handy later.

Step-by-Step Replacement Guide

Think of this as a spa day for your printer—out with the old, in with the new! While each printer model has its quirks, here’s the general approach to installing your laser printer maintenance kit:

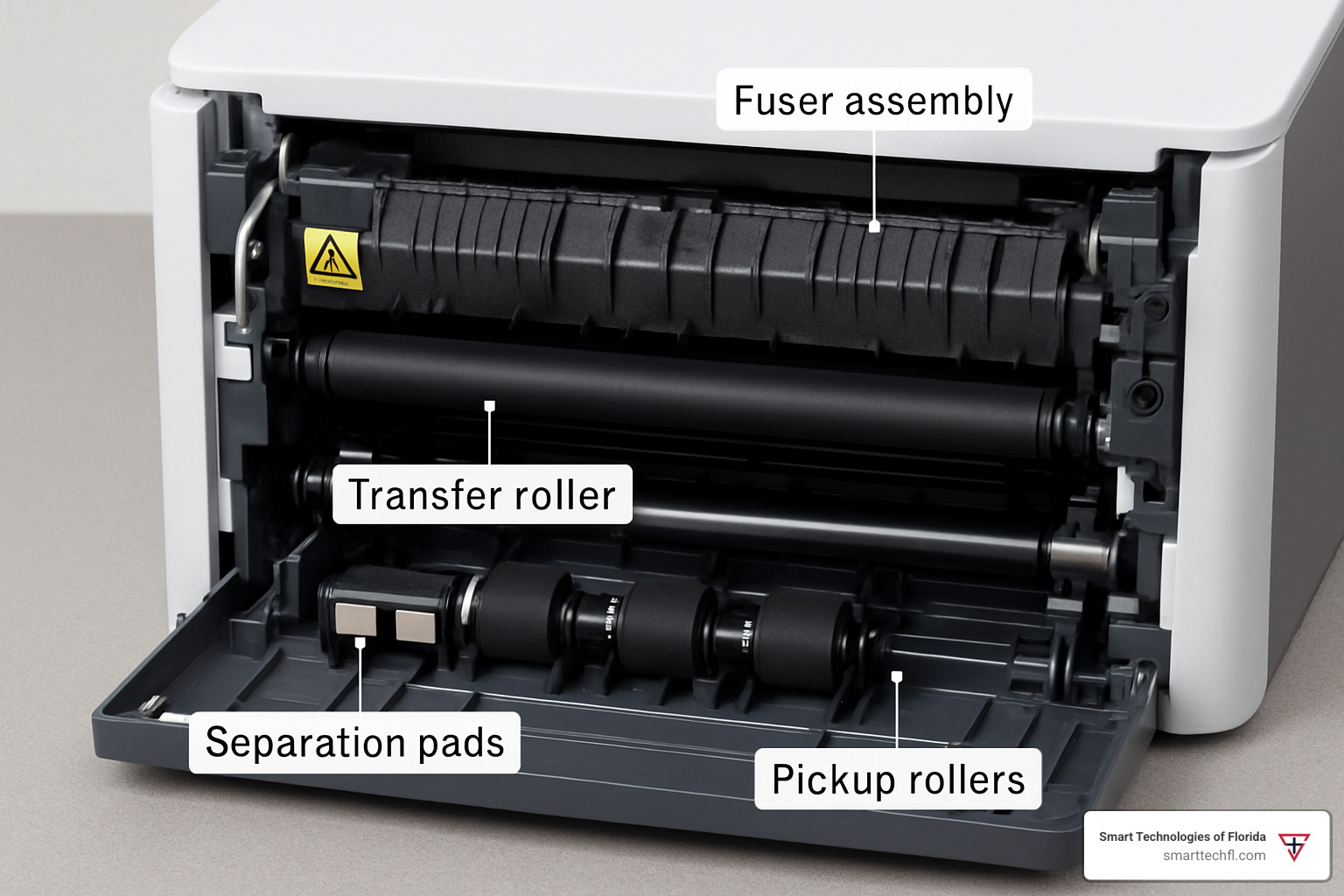

First, access your printer’s internal components by removing paper trays and opening access panels. Some models will need you to remove the toner cartridge too.

Next, locate and remove the old fuser assembly—usually found at the back where paper exits. You’ll typically need to loosen some screws and disconnect electrical connectors before sliding it out. Handle it carefully, even after cooling.

The transfer roller is usually hiding under where the toner cartridge sits. When replacing it, remember the golden rule: never touch the roller surface with bare hands. Skin oils can cause print quality issues that’ll have you scratching your head for weeks.

For pickup rollers and separation pads, you’ll be working around the paper trays. These small but mighty components prevent paper jams, so take your time installing them correctly. Make sure they click or lock into place—if they feel loose, something’s not right.

Once all components are replaced, take a moment to clean the paper path with a slightly dampened lint-free cloth. You’d be amazed at the paper dust that accumulates in these machines!

When installing the new fuser, alignment is crucial. Slide it in carefully along the guide rails until it seats properly, reconnect any electrical connections, and secure it with screws if needed.

After reassembling everything, don’t forget the crucial step of resetting the maintenance counter through your printer’s control panel. This step varies by manufacturer, but skipping it means your printer will still think it needs maintenance!

Troubleshooting Common Installation Hiccups

Even the smoothest installations sometimes hit a snag. Here are solutions to the issues we see most often:

If you’re getting error messages about the fuser or experiencing paper jams, your fuser might not be seated properly. Power down, open things back up, and check that it’s aligned correctly on both sides with all electrical connections secure.

When papers refuse to feed or multiple sheets feed at once, your pickup rollers or separation pads might need adjustment. Make sure they’re installed correctly and can move freely.

Poor print quality after installation usually points to transfer roller issues. Double-check that it’s properly seated and not touching anything it shouldn’t be.

Persistent error messages often mean the maintenance counter hasn’t been properly reset. Some printers are particularly finicky about this step and may require specific sequences or service codes.

I remember helping a local Daytona Beach accounting firm during tax season when their newly installed kit wasn’t working right. The culprit? A tiny shipping clip they’d forgotten to remove from the new fuser. These little details can make all the difference!

If troubleshooting doesn’t solve your problem, don’t hesitate to reach out for professional help. DIY maintenance is great, but sometimes you need an experienced hand—that’s what we’re here for at Smart Technologies of Florida. After all, your printer is too important to your business to stay down for long.

For more detailed guidance, HP offers excellent printer maintenance kit resources specific to their models, and our team has put together helpful Printer Maintenance 101: Tips that cover additional maintenance best practices.

Maximizing Printer Life After the Kit

Installing a laser printer maintenance kit is just one part of the journey toward extending your printer’s lifespan. With our 23 years of experience working with businesses in Daytona Beach and beyond, we’ve seen how a few simple practices can transform a printer from a constant headache into a reliable workhorse.

Think of your printer as you would your car—regular oil changes (maintenance kits) are essential, but so is keeping it clean, using quality fuel, and driving it responsibly. Let’s explore how to keep your printer purring along after that maintenance kit installation.

Regular cleaning makes a world of difference. A quick monthly dust-off with electronics-safe compressed air prevents buildup that can damage sensitive components. For multifunction devices, a weekly wipe of the scanner glass with a soft cloth can prevent those mysterious streaks that appear on your scans. One of our clients joked that their scanner was “adding artistic interpretation” to their documents before they started this simple cleaning routine!

The paper you choose matters more than you might think. High-quality paper appropriate for your specific printer not only produces better results but creates less dust and debris inside your machine. Before loading paper, give it a quick fan to separate the sheets—this simple five-second habit can prevent countless paper jams. And remember those maximum fill lines on your paper trays? They’re not just suggestions!

Your printer’s environment plays a surprisingly important role in its longevity. Printers don’t enjoy extreme temperatures any more than we do—keep them in well-ventilated areas away from direct sunlight, heating vents, or freezing windows. Stable power is also crucial; a good UPS (uninterruptible power supply) can protect your printer from power surges that might otherwise fry its sensitive electronics.

Don’t overlook software updates. Printer firmware updates aren’t just about adding new features—they often include fixes for performance issues and compatibility improvements. Setting aside a few minutes each quarter to check for and install updates can save hours of troubleshooting down the road.

When it comes to disposing of old parts, think green. Many manufacturers offer fuser core exchange programs where you return your old components for recycling. One small office we work with set up a simple cardboard box labeled “printer recycling” to collect used toner cartridges and maintenance kit components—when it’s full, they drop everything off at appropriate recycling points. Small steps like this keep harmful materials out of landfills.

For many busy organizations, a managed print service provides peace of mind. At Smart Technologies of Florida, our managed services include proactive monitoring that can detect issues before they become problems. As one office manager told us, “It’s like having a printer guardian angel—the maintenance kit arrived the day before we got our first warning message!” Our flexible support options can be custom to fit your specific needs.

The statistics speak for themselves—printers that receive regular maintenance and care typically last 2-3 times longer than neglected ones. One healthcare client has a printer that’s processed over 2 million pages through multiple maintenance cycles—far exceeding its expected lifespan and saving thousands in replacement costs.

A laser printer maintenance kit installation isn’t the end of printer care—it’s a fresh beginning. With these simple practices, your newly maintained printer can provide years of reliable service, keeping your business documents flowing smoothly while protecting your technology investment.

Frequently Asked Questions About Laser Printer Maintenance Kits

How often should I replace a kit?

When clients ask me about timing for laser printer maintenance kit replacements, I always tell them it’s like changing the oil in your car—it depends on how much you drive!

For most business printers, manufacturers design these kits to last through a specific number of pages. Enterprise-grade machines typically need a refresh after 200,000-250,000 pages, while smaller office workhorses might need attention after 50,000-100,000 pages.

In real-world terms, this usually means:

If your office is printing constantly (10,000+ pages monthly), you’re looking at replacement every 12-18 months. For moderate users printing 2,000-10,000 pages monthly, your kit might last 18-36 months before needing attention. And if your printing is lighter (under 2,000 pages monthly), you might go 3-5 years before replacement.

That said, your printer will often tell you when it’s time—regardless of the page count. If you’re experiencing persistent paper jams that make you want to kick the machine, print quality issues that no amount of toner-shaking can fix, or direct error messages about maintenance needs, it’s time for a kit.

I recommend my clients check their printer’s page count quarterly (it’s usually available through the printer’s control panel) and compare it to the manufacturer’s recommendations. This simple habit helps you plan ahead and avoid that dreaded mid-deadline printer breakdown!

Can I swap just one component instead of the whole kit?

“Can’t I just replace the part that’s broken?” This question comes up often, and while technically yes—you can purchase individual components like fusers or rollers separately—there’s a good reason maintenance components come bundled together.

Think of it like replacing just one tire on your car when all four are worn. It might get you back on the road, but it’s rarely the best approach. The laser printer maintenance kit components typically wear at similar rates, working together as a system. When one part starts failing, others are usually not far behind.

From a practical standpoint, buying the complete kit is usually more cost-effective than purchasing components individually. Plus, it gives your printer a comprehensive refresh, minimizing the chance you’ll need to open up the machine again in a month when another part fails.

The one exception might be if a specific component fails unusually early due to a paper jam or other incident. In those rare cases, replacing just that component might make sense—but for normal wear and tear, the complete kit is almost always your best bet.

Are maintenance kits covered under warranty?

Warranty coverage for laser printer maintenance kits can be a bit tricky, and I’ve helped many confused clients steer this territory.

Most standard printer warranties treat maintenance kits like the brake pads on your car—they’re expected to wear out eventually. If a brand new kit fails within days of installation (before its rated page count), that’s typically covered. But normal wear and tear requiring scheduled maintenance usually isn’t included in basic warranties.

The good news? Many extended warranties and service contracts do include maintenance kits. If you’ve invested in one of these plans, check your agreement carefully—you might be pleasantly surprised to find coverage.

Don’t forget that the maintenance kit itself typically comes with its own warranty (usually one year or a specified page count) that protects you against defects in the components.

One important note: some manufacturers require professional installation to maintain warranty coverage. While many of our clients successfully install kits themselves, others prefer our technicians handle it to preserve their warranty protection.

At Smart Technologies of Florida, we’re always happy to review your specific warranty terms and help you understand your options. Our goal is finding the most cost-effective approach to keeping your printers running smoothly—whether that means utilizing warranty service or scheduling preventative maintenance.

Conclusion

Understanding and properly maintaining your printer with a laser printer maintenance kit isn’t just smart—it’s an investment that pays dividends in productivity and cost savings. These kits aren’t another expense to begrudgingly add to your budget; they’re a strategic approach that keeps your business running smoothly when you need it most.

The numbers tell a compelling story: printers that receive regular maintenance can soldier on for over 2 million pages across many years of loyal service. Meanwhile, those pesky paper jams that interrupt your workday can be reduced by up to 80% with proper maintenance. When you weigh the cost of a maintenance kit (typically 35-50% of a new printer’s price) against the expense and hassle of replacing your printer prematurely, the value becomes crystal clear.

Here at Smart Technologies of Florida, we’ve spent 23 years helping businesses in Daytona Beach and beyond transform their operations. We’ve seen how a well-maintained printer becomes an unsung hero in the office—quietly supporting your team without drama or disruption. Our people-centric approach recognizes that printer maintenance isn’t just about machinery and components—it’s about keeping your business flowing without the frustration of unexpected downtime.

Whether you’re a DIY enthusiast who enjoys rolling up your sleeves to install maintenance kits yourself, or you prefer to leave the technical details to our experts for a hands-off experience, the key is making printer maintenance a regular part of your operations. Think of it as preventative healthcare for your office equipment—regular checkups now prevent emergency room visits later!

For more information about printers, copiers, and how we can help transform your business operations through strategic digital solutions that actually make sense for your unique needs, visit our printers and copiers page or reach out to our team today.

Remember: The few minutes you spend on maintenance today saves hours of frustration (and a chunk of your budget) tomorrow. Your future self—and your accounting department—will definitely thank you.