Wide Format Printing 101: Because Size Matters

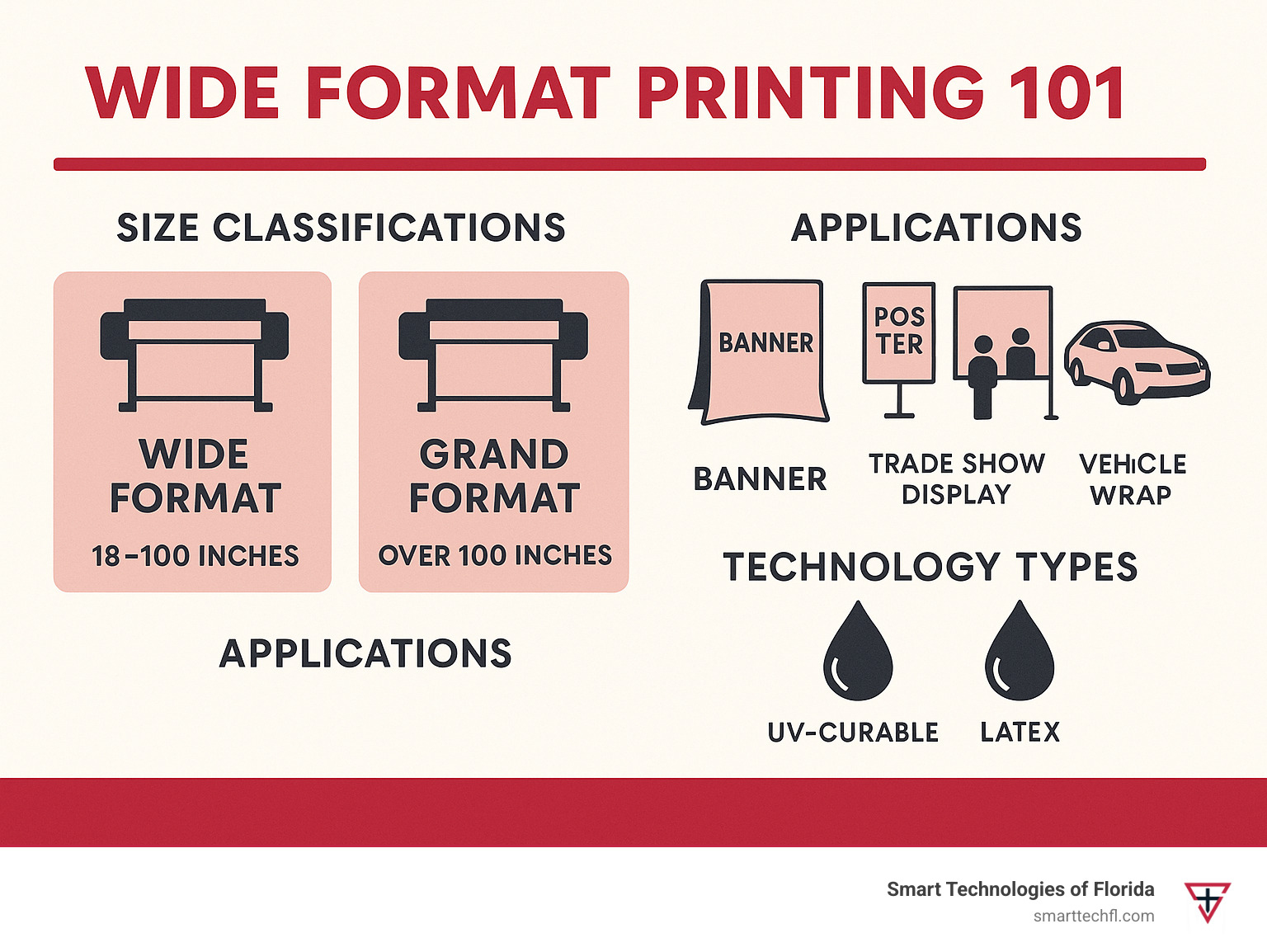

Wide format printing refers to specialized printing that handles media widths between 18 and 100 inches, perfect for creating large-scale graphics that grab attention from a distance. This technology has transformed how businesses communicate visually, from eye-catching banners to building-sized murals.

Quick Answer for Wide Format Printing:

- Size Range: 18-100 inches wide (larger than standard office printers)

- Common Uses: Banners, posters, trade show displays, vehicle wraps, signage

- Key Benefit: High-impact visuals visible from far distances

- Market Growth: $10.04 billion industry growing 4.36% annually through 2029

- Main Technologies: Inkjet printing with UV-curable, latex, or eco-solvent inks

Here’s the reality: size absolutely matters in today’s competitive marketplace. While your competitors stick to standard 8.5×11 inch flyers, wide format printing lets you create massive visual displays that stop people in their tracks.

The technology traces back to rock musician Graham Nash, who adapted an IRIS 3047 printer in the 1980s to create large fine art prints. What started as an artistic experiment has evolved into a $10+ billion industry that’s reshaping advertising, retail displays, and business communications.

Today’s wide format printers can handle everything from flexible vinyl banners to rigid substrates like wood and metal using advanced inkjet technology with UV-curing inks that are both environmentally friendly and incredibly durable.

Wide Format Printing Explained

Think of wide format printing as the sweet spot between regular office printing and those massive billboards you see on highways. It’s where businesses go when they need to make a real visual impact without breaking the bank.

The numbers tell an exciting story. The global large format printing market hit $10.04 billion in 2024 and is racing toward $12.43 billion by 2029. That’s a solid 4.36% compound annual growth rate, according to the latest research on market growth.

| Format Type | Width Range | Best For | Viewing Distance |

|---|---|---|---|

| Wide Format | 18-100 inches | Banners, displays, vehicle wraps | 10-50 feet |

| Large Format | 18-200+ inches | All oversized printing | 10-100+ feet |

| Grand Format | 100+ inches | Billboards, building wraps | 100+ feet |

Definition & Size Ranges

Wide format printing covers everything from 18 to 100 inches wide. That’s roughly 1.5 feet to 8 feet across – perfect for creating graphics that people can actually see and read from a reasonable distance.

At 18 inches wide, you’re creating something substantial enough to catch someone’s eye across a room. At 100 inches wide, you’re approaching the limits of what most buildings can accommodate while still being cost-effective.

The categories break down simply: small format handles up to 17 inches (your typical office printer), wide format spans 18-100 inches (the business workhorse), and super-wide or grand format goes beyond 100 inches (the attention-grabbers you see from highways).

Evolution & Milestones

The story of wide format printing starts in the most unexpected place – a rock star’s studio. In the mid-1980s, Graham Nash from Crosby, Stills & Nash got fascinated with digital imaging. He took an IRIS 3047 printer and turned it into an art-making machine for large fine art prints.

Nash probably had no idea he was launching an entire industry. His Nash Editions became the pioneer of wide format fine art reproduction, proving that digital printing could create museum-quality pieces at sizes that traditional methods couldn’t match.

The 1980s brought the digital boom that changed everything. The industry shifted from clunky electrostatic methods to precise inkjet technology. Today’s technology would blow Nash’s mind – modern systems can create seamless prints up to 600 square meters.

Wide Format Printing vs Large & Grand Format

Wide format (18-100 inches) handles the everyday heroes of business communication. Think trade show displays, retail signage, and vehicle graphics. These projects use roll-to-roll printers for flexible materials like vinyl and canvas, or smaller flatbed systems for rigid substrates.

Grand format (100+ inches) enters billboard territory. These are the massive building wraps and highway advertisements designed for long-distance viewing.

Most businesses find their sweet spot in wide format because it delivers maximum impact at reasonable costs while fitting into normal commercial spaces and workflows.

Technology, Media & Sustainability

Modern wide format printing technology uses incredibly precise inkjet printheads that can place microscopic droplets exactly where they need to go, while new ink formulations actually help protect our environment instead of harming it.

UV-curable inks contain absolutely no solvents and emit zero harmful volatile organic compounds (VOCs) when they cure. Compare that to traditional solvent-based inks, which can contain over 70% volatile organic compounds.

Core Printing Technologies

The magic behind wide format printing starts with piezo-electric drop-on-demand printheads, which give incredible control over every tiny droplet of ink. These systems can produce droplets measured in picoliters – smaller than a human cell.

UV-curable ink systems cure instantly using LED or mercury vapor lamps, with no VOC emissions. The adhesion to different materials is excellent, and fade resistance for outdoor applications is superior to older technologies.

Latex ink technology offers water-based inks with tiny polymer particles that create incredibly durable prints. They’re environmentally friendly with low odor, and many applications don’t need lamination for protection.

Substrates & Roll/Flatbed Workflow

Roll-fed systems are perfect for flexible materials like vinyl banners, canvas, fabric, paper, and window films. They can handle long runs – imagine printing a seamless graphic that’s 100 feet long.

Flatbed systems handle rigid plastic sheets, wood panels, metal sheets, glass, and corrugated plastic boards. The vacuum systems hold materials in place with zones that can be adjusted for irregularly shaped pieces.

Green Printing Practices

Sustainability in wide format printing has evolved from a nice-to-have feature to an absolute necessity. UV-curable inks offer 100% of the ink ending up on your media, zero VOC emissions during curing, reduced energy consumption, and longer-lasting prints.

Water-based latex systems contain no hazardous air pollutants, produce prints safe for indoor environments, often use renewable and recyclable media options, and require no special ventilation systems.

For more detailed information about wide format printers and their capabilities, and to learn more about the scientific research on environmental benefits of UV printing, these technologies continue to evolve toward even greater sustainability.

Applications, Finishing & Industry Trends

The true power of wide format printing reveals itself when you see how it transforms businesses across every industry imaginable. From retail window displays to massive building wraps, wide format printing captures attention and communicates messages effectively.

In Florida, we see incredible diversity of applications. During race season in Daytona, the entire city transforms with racing-themed graphics, banners, and vehicle wraps. Year-round, our hospitality and tourism industries rely on wide format printing to create memorable experiences for millions of visitors.

Industry Use-Cases

Advertising and out-of-home marketing drives much of the wide format printing industry’s growth. Billboard companies and outdoor advertising specialists have found that wide format technology gives them incredible creative freedom while maintaining durability for outdoor exposure.

Retail environments use wide format printing to create shopping experiences that engage emotions. Window graphics change with seasons, in-store promotional banners guide shoppers, and floor graphics provide wayfinding in large retail spaces.

The architecture, engineering, and construction industry uses wide format printing beyond traditional blueprints. Construction sites use wide format graphics for safety signage, architects specify decorative wall coverings, and wayfinding systems for large facilities rely on wide format printing.

Fine art and photography continue to benefit from the technology Graham Nash pioneered. Giclée printing has become the gold standard for fine art reproduction, allowing artists to create limited edition prints that rival original works.

Finishing & Post-Processing

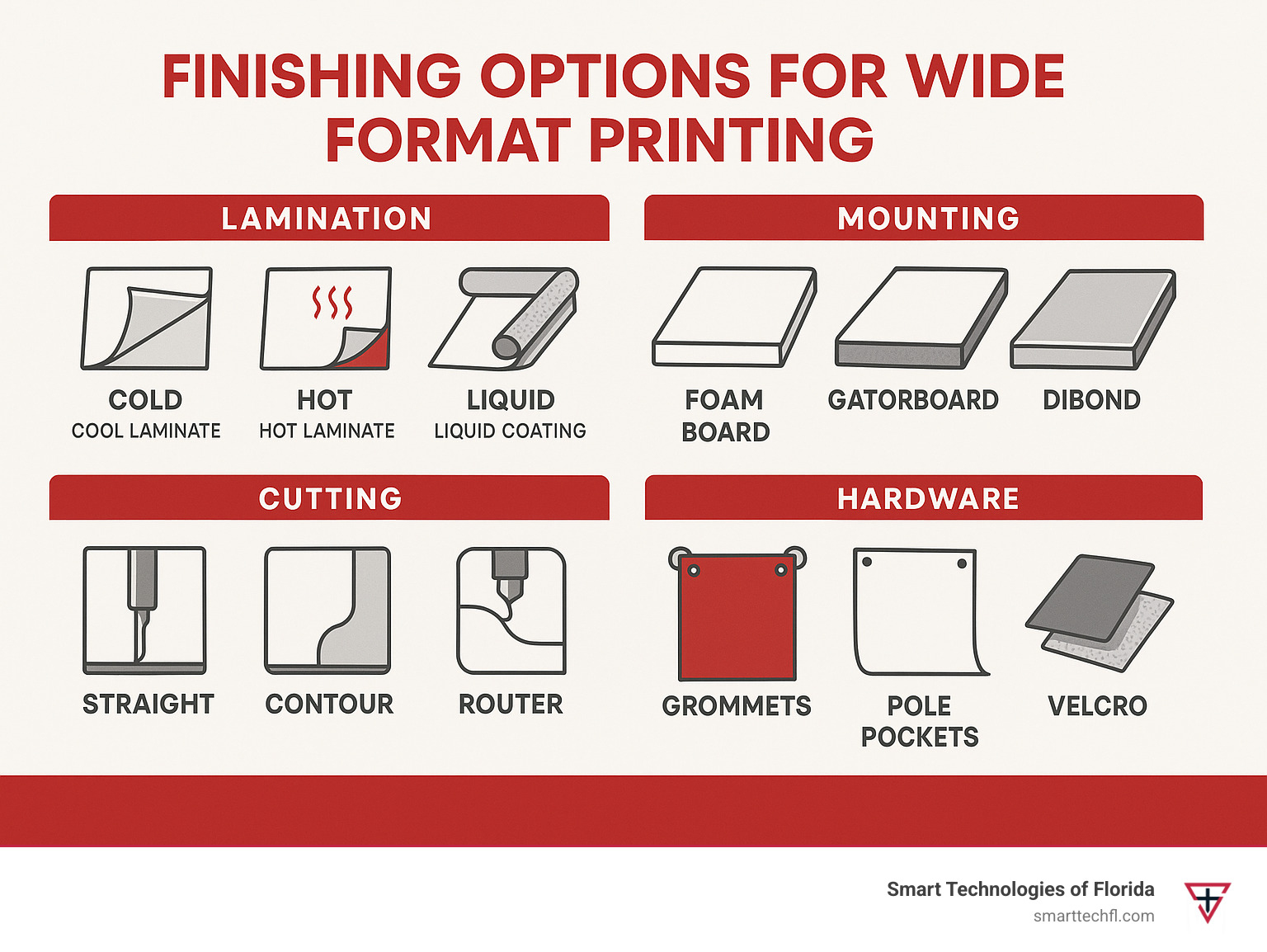

Professional finishing transforms printed graphics into durable, professional installations that can withstand any environment.

Lamination serves as your graphics’ protective shield. Cold lamination uses pressure-sensitive films at room temperature, while hot lamination creates stronger bonds for outdoor applications.

Mounting options include foam board for lightweight displays, Gatorboard for better resistance to warping, and Dibond aluminum composite for premium installations with exceptional durability.

Cutting and shaping capabilities include contour cutting for custom shapes, router cutting for rigid substrates, and laser cutting for intricate designs.

Emerging Trends & Innovations

Internet of Things integration is changing how print shops operate. Modern wide format printers connect to the internet, monitoring performance and automatically ordering supplies.

Artificial intelligence in color management maintains consistent colors across different materials and environmental conditions. AI-powered systems automatically adjust for substrate variations.

Textured and dimensional printing adds sensory dimensions to graphics. New ink formulations create raised surfaces that invite touch interaction, particularly valuable for retail displays.

Web-to-print automation streamlines the entire ordering and production process with online systems that reduce turnaround times while minimizing errors.

Choosing & Preparing for Your Wide Format Printing Project

Getting your wide format printing project right the first time comes down to smart planning and understanding what goes into a successful print job. After 23 years in the business, we’ve learned that the projects that go smoothest are the ones where clients understand the technical side upfront.

Proper file preparation, choosing the right materials, and planning your finishing options saves you time, money, and headaches down the road.

Evaluating Printer Specs

When considering wide format printing, understanding printer capabilities helps you set realistic expectations and communicate clearly with your print provider.

Resolution is your quality foundation. Most wide format applications need 100-150 DPI at the final print size. Indoor applications like trade show displays benefit from 150-300 DPI. Outdoor signage works perfectly at 75-150 DPI since viewing distances are much greater.

Print speed affects both timeline and budget. Modern printers offer multiple quality modes. Production mode balances speed with quality for most commercial work. High quality mode takes longer but delivers premium results when you need to make a lasting impression.

Media width determines what’s possible without seaming. A 44-inch printer covers most banner and display needs. When you get to 60-inch printers, you can tackle larger banners and vehicle graphics.

The SureColor T7270D represents what’s possible with today’s technology – professional results with efficiency that keeps projects on schedule and budget.

File Preparation & Workflow

Unlike small format printing where minor issues might slide by unnoticed, wide format magnifies everything. That tiny color inconsistency becomes obvious on a 10-foot banner.

Getting your resolution right requires simple math. That 100-150 DPI rule means a 48″ x 96″ banner at 150 DPI needs a file that’s 7,200 x 14,400 pixels.

Color management makes the difference between “close enough” and “exactly right.” PDF files with embedded fonts and images are the gold standard. Adobe Illustrator files keep vector graphics sharp at any size.

Bleed prevents white edges. Most wide format graphics need 0.125″ to 0.25″ of extra image area beyond the final trim size.

Costing & Scheduling

Understanding wide format printing costs helps you budget smartly and avoid surprises. Premium substrates cost more than basic banner material. Heavy ink coverage uses more ink and increases costs. Finishing options like lamination and mounting add to both cost and timeline.

Smart scheduling saves money and stress. Planning ahead rather than rushing gives your print provider time to work efficiently. When you group similar projects together, setup time gets spread across multiple jobs, often reducing per-piece costs.

For keeping your wide format printing equipment running smoothly, our printer maintenance tips guide covers everything you need to know about maintaining optimal performance.

Frequently Asked Questions about Wide Format Printing

What materials can I print on?

One of the most exciting aspects of wide format printing is the incredible variety of materials you can work with.

Flexible materials form the backbone of most wide format projects. Vinyl remains the workhorse because it’s versatile, weather-resistant, and cost-effective. Canvas brings an upscale, artistic feel to projects. Fabric has become popular for trade show displays because it’s lightweight and creates a sophisticated look.

Rigid substrates open up different possibilities. Foam board and Gatorboard create professional displays that stand up on their own. Dibond aluminum composite panels handle outdoor weather for years. Acrylic creates stunning backlit displays that make colors pop.

Specialty materials solve specific challenges. Window films transform glass surfaces into advertising space, magnetic materials create removable vehicle graphics, and reflective media ensures visibility for safety applications.

How do I ensure colour accuracy?

Color accuracy can make or break a wide format printing project. Achieving accurate colors requires attention to a few key details.

Monitor calibration is your foundation. If your computer monitor isn’t showing colors accurately, everything else falls apart. Professional monitor calibration ensures what you see on screen matches what comes off the printer.

Color profile management ensures everyone speaks the same color language. ICC color profiles act like translators, converting your design colors into instructions the printer understands perfectly.

The proofing process is your safety net. We always recommend printing a small sample before committing to the full job. A 12″ x 18″ proof costs a fraction of a full banner but shows you exactly how colors will appear.

What’s the maximum size you can print?

The beauty of wide format printing is that size limitations are mostly about logistics rather than technology. Most commercial wide format printers handle widths up to 100 inches, but length is virtually unlimited with roll-fed systems.

Standard wide format capabilities cover the vast majority of projects. With widths from 18 to 100 inches and unlimited length, you can create seamless graphics for most applications.

When projects exceed 100 inches wide, grand format printers step in to handle the challenge. These industrial machines can print widths exceeding 16 feet, making billboards and massive architectural graphics possible as single, seamless pieces.

The current record holder is Big Image’s ‘Infinitus’ printer, capable of producing seamless prints up to 600 square meters. For most business applications, standard wide format dimensions provide plenty of creative freedom while keeping projects manageable and cost-effective.

Conclusion

Wide format printing has evolved from Graham Nash’s artistic experiments in the 1980s into a $10+ billion industry that’s changing how businesses communicate with the world.

When everyone else is handing out business cards and letter-sized flyers, you could be creating graphics that stop traffic. That’s the power of going big with your visual communications.

The technology tells an amazing story. We’ve moved from early electrostatic printers to today’s sophisticated systems that can print seamlessly on materials up to 600 square meters. Modern UV-curable inks cure instantly without releasing harmful chemicals, while latex systems create durable prints that are safe for any environment.

Wide format printing isn’t just about making things bigger – it’s about making a bigger impact. Whether you’re wrapping a vehicle, creating a trade show display, or installing architectural graphics, this technology gives you tools that transform how people see your business.

The environmental benefits make this an easy choice for forward-thinking companies. Today’s printing technologies use less energy, produce less waste, and create longer-lasting graphics than ever before.

At Smart Technologies of Florida, we’ve spent 23 years helping businesses transform how they operate and communicate. We’ve seen how the right visual communication strategy can change everything from customer perception to employee morale.

Your next big idea deserves to be seen from a distance. Whether it’s a 10-foot banner announcing your grand opening or a building wrap that turns your entire facility into a marketing message, wide format printing gives you the canvas to paint your business story as large as your ambitions.

The technology is ready. The materials are available. The only question left is: how big are you willing to think?

Ready to transform your visual communications? Contact Smart Technologies of Florida today, and let’s explore how wide-format printer solutions can help your business make the impact it deserves.