Don’t Get Jammed Up! Essential Laser Printer Maintenance Tips

Laser printer maintenance tips are essential for keeping your business equipment running smoothly and avoiding costly downtime. Here’s a quick overview of the most important maintenance tasks:

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Clean exterior & paper path | Monthly | Prevents dust buildup and paper jams |

| Replace toner when indicated | As needed | Protects internal components |

| Clean rollers | Quarterly | Ensures reliable paper feeding |

| Run printer utilities | Monthly | Detects issues early |

| Use correct paper type | Always | Prevents jams and extends printer life |

Your laser printer is the unsung hero of your retail business, bridging the digital and physical worlds by producing everything from invoices to promotional materials. Like any workhorse, it requires regular care to deliver consistent performance.

The average printer lifespan ranges from 3-7 years, but with proper maintenance, you can significantly extend this timeframe while maintaining print quality. According to industry data, replacing worn parts like fusers, imaging drums, and rollers at the right intervals can restore print quality and extend a laser printer’s life up to 300,000 pages.

Many business owners overlook printer maintenance until paper jams or poor print quality disrupt their workflow. By then, you’re dealing with frustrated staff, delayed customer service, and potential repair costs that could have been avoided.

“Printer rollers are the unsung heroes behind reliable printing,” notes one industry expert. When these components collect dust, toner residue, or simply wear down, your printer’s reliability suffers.

The good news? Most laser printer maintenance is straightforward and can be performed in-house with minimal tools and time investment. Implementing a regular maintenance schedule not only prevents breakdowns but also ensures consistent print quality and lower operating costs over time.

1. Control the Environment First

The secret to a long-lasting laser printer starts before you even touch the machine itself. Let’s talk about creating the perfect home for your printer—something we’ve learned makes a world of difference for our clients in Daytona Beach and beyond.

Your laser printer is a bit like Goldilocks—it wants conditions that are just right. For optimal performance, aim to keep your office temperature between 60-75°F (15-24°C) with humidity levels of 40-60%. This sweet spot prevents paper from becoming too crispy (hello, static electricity and paper jams) or too damp (which leads to feeding problems that make everyone in the office groan).

Dust is your printer’s arch-nemesis. Even in what appears to be a spotless office, tiny particles are floating around, just waiting to settle inside your printer and wreak havoc on sensitive components.

“I’ve seen printers fail years before their time simply because they were placed in high-traffic areas where dust was constantly being kicked up,” shares one of our technicians. “It’s such an easy problem to prevent.”

Airflow matters tremendously. Position your printer in a well-ventilated space to prevent overheating, but be strategic—placing it directly under an AC vent is like giving it a dust shower every hour. A balance of good air circulation without direct blasts of air is ideal.

A simple printer cover when the device isn’t being used can work wonders for dust protection. Think of it as tucking your printer in at night—a small gesture that adds years to its life. Many of our clients have reported fewer maintenance issues after adopting this simple habit.

Static protection becomes especially important during Florida’s drier winter months. Static not only causes those annoying paper jams but can actually damage electronic components inside your printer. A small humidifier nearby might seem like overkill, but it’s cheaper than a new printer!

Here in our Daytona Beach office, we’ve finded that coastal humidity presents its own challenges. During our steamier summer months, we sometimes place a small dehumidifier near our printer bank to keep moisture levels in check. This simple adjustment has dramatically reduced paper feeding issues for our team and many of our clients.

Remember: before you worry about cleaning schedules and maintenance routines, getting your printer’s environment right is the foundation of all good laser printer maintenance tips. It’s like building a house—you need a solid foundation before anything else matters.

2. Power Down Properly & Cool Before Touching Anything

Let’s talk about something that might seem obvious but is surprisingly often overlooked – how to safely power down your printer before maintenance. I’ve seen many well-intentioned office managers dive straight into cleaning their printers without taking proper precautions.

Always use your printer’s shutdown button rather than yanking the plug from the wall. This isn’t just good manners for your electronic friend – it allows the printer to complete its internal shutdown sequence, which helps protect the cartridge and properly position internal components for their “rest period.”

Once powered down properly, unplug the printer completely from the wall outlet. This simple step eliminates any risk of electrical shock (trust me, printer maintenance shouldn’t be an electrifying experience!) and protects against unexpected power surges while you’re working.

Now comes the part that requires patience – allow your printer to cool down for at least 30-60 minutes before opening any panels. Laser printers run hot – really hot. The fuser assembly can reach temperatures up to 400°F (200°C), which is hot enough to cause serious burns.

As my colleague at Smart Technologies of Florida likes to say, “Approaching printer maintenance is like preparing for a first date – rushing things will only lead to regret.”

Safety-first laser printer maintenance tips

When it’s finally time to perform your maintenance, keep these safety measures in mind:

Ground yourself before touching internal components to prevent static electricity damage (those tiny electronic parts are sensitive souls). Avoid exposing the imaging drum to bright light sources – this photosensitive component can be permanently damaged by direct sunlight or intense fluorescent lighting.

Protective gear matters too. Slip on disposable gloves to keep toner particles off your skin and consider wearing a simple face mask to avoid breathing in toner dust. Make sure your workspace is well-ventilated to clear away any airborne particles.

“I once had a client who tried cleaning their printer immediately after a print job,” shares one of our technicians. “Not only did they burn their fingers, but the cleaning solution they used evaporated instantly on the hot components, leaving more residue than when they started.”

Toner is designed to melt when heated – that’s literally how it works! Cleaning a hot printer can actually spread toner around rather than removing it, creating an even bigger mess. Patience now means less frustration later.

Taking these few extra minutes for proper shutdown and cooling isn’t just about safety – it’s about ensuring your laser printer maintenance tips actually work effectively, saving you time and extending your printer’s life in the long run.

3. Monthly Dust-Down: Exterior & Paper Path

There’s something deeply satisfying about a freshly cleaned printer, isn’t there? One of the most impactful laser printer maintenance tips you can follow is a simple monthly dust-down of your machine’s exterior and paper path. Think of it as a mini spa day for your hardworking office companion!

Start with the outer surfaces using a soft, lint-free cloth slightly dampened with water. For those stubborn coffee splashes or ink marks, a mild cleaner works wonders—but remember to apply it to your cloth first, never directly on the printer. Spraying liquids directly onto electronic equipment is asking for trouble!

“Many users end up throwing away the printer manual and then struggle with basic upkeep later,” one of our maintenance specialists often reminds clients. Keep that manual somewhere accessible—it’s your roadmap to properly accessing internal components for cleaning.

When it comes to cleaning the paper path, a little patience goes a long way. Remove all paper from trays first, then gently open access doors according to your printer’s manual. Use a dry, lint-free cloth to wipe away visible dust and debris. For those frustrating hard-to-reach spots (we all know they’re there!), a soft artist’s paintbrush works wonders. Avoid using toothbrushes—they’re too abrasive and can scratch delicate components.

Here at Smart Technologies of Florida, we’ve finded that a fine-tipped paintbrush is our secret weapon for reaching dust in tight printer corners without causing damage. It’s an inexpensive tool that delivers impressive results!

When you encounter toner particles, reach for a toner-activated cloth specifically designed for this purpose. These specialized cloths work like magnets for toner particles, trapping them rather than smearing them around and creating a bigger mess. A computer vacuum with a HEPA filter can also safely remove loosened particles without risk of static discharge.

Quick laser printer maintenance tips for home users

Home users with lighter printing demands can benefit from a simplified 5-minute monthly routine. Power off your printer properly using its power button (never just yank the cord!), then give exterior surfaces a quick wipe with a slightly damp microfiber cloth. Remove and inspect paper trays, wiping away any paper dust that’s accumulated. Take a moment to peek inside and remove any paper scraps hiding in the paper path.

“Giving your printer a quick ‘spa day’ once a month will make it thank you with crisp, clean documents for years to come,” as one of our cheerful service technicians likes to say. And don’t forget to cover your printer when it’s not in use—this simple habit dramatically reduces dust buildup.

For those who want to dive deeper into printer maintenance best practices, we’ve put together a comprehensive guide in our Laser Printer Maintenance Checklist: Tips for Longevity & Performance. It’s worth bookmarking for future reference!

4. Deep-Clean Toner Cartridge, Drum & Fuser

Let’s get our hands dirty—well, not literally! When it comes to thorough laser printer maintenance tips, cleaning the toner cartridge, drum unit, and fuser assembly requires special care. These components are the heart and soul of your printer, directly impacting those crisp documents you need for client meetings.

First things first—remember our golden rule: power off, unplug, and let that printer cool completely. Your fingers will thank you later!

When handling the toner cartridge, think of it as a delicate piece of technology (because it is). Place it on some scrap paper to catch any toner that might escape during your cleaning session. If you’re installing a new cartridge, give it a gentle shake first—think of it as waking up the toner particles so they distribute evenly.

“Toner particles are like the glitter of the office world,” jokes one of our technicians at Smart Technologies. “Once they escape, you’ll be finding them everywhere for weeks. That’s why using a toner-activated cloth is essential—it grabs those particles instead of spreading them around.”

The imaging drum deserves even more tender loving care. Always grip it by the edges only—fingerprints on the green or blue surface are like permanent scars that will show up on every print. And keep it away from bright light! The drum is like a vampire—exposure to direct light can damage it permanently.

When it comes to the fuser assembly, less is often more. This component typically doesn’t need regular cleaning but will likely need replacement after about 100,000 pages. If you can access it in your printer model, a gentle wipe with a dry, lint-free cloth is all it needs. Never use cleaning solutions unless your manufacturer specifically recommends them—the wrong chemical can damage the heat rollers and lead to costly repairs.

For specific instructions custom to your printer model, the Step-by-step HP guide is an excellent resource, as is your printer’s manual (you know, that booklet you probably tucked away somewhere safe and now can’t find).

Expert-level laser printer maintenance tips for spotless prints

For those of you who demand perfection from every printed page, here are some advanced techniques we’ve perfected over our 23 years in the business:

Avoid fingerprints on the drum at all costs—even the natural oils from your skin can create permanent marks that show up on prints. When cleaning corona wires (those thin wires that help transfer toner to paper), use a cotton swab with a tiny amount of 99% isopropyl alcohol and the gentlest touch imaginable.

“We had a client who was getting mysterious spots on every document,” recalls our senior technician. “Turned out they had been aggressively cleaning their printer’s drum with paper towels. The tiny scratches were causing toner to collect in spots. After replacing the drum and showing them proper cleaning techniques, their print quality was restored.”

Most fusers should be replaced around the 100,000-page mark. Even before you see obvious print quality issues, preventive replacement can save you from the frustration of documents failing at critical moments.

One final pro tip: after replacing toner, run a cleaning sheet through your printer. This simple step helps remove any residual toner that might have escaped during the replacement process, ensuring your next important document doesn’t come out with unexpected smudges.

With these careful maintenance practices, your printer will reward you with consistently professional output that makes your business look its best—because at Smart Technologies of Florida, we believe even the smallest details contribute to your professional image.

5. Keep Rollers Jam-Free

There’s nothing quite as frustrating as hearing your printer grind to a halt mid-job with that dreaded paper jam message. In our 23 years of experience at Smart Technologies of Florida, we’ve found that the humble roller is often the unsung villain behind these workplace interruptions.

Rollers are the rubber components that physically move paper through your printer, and they need regular TLC to keep your workday flowing smoothly. Think of them as the tires on your car—they wear down over time and occasionally need maintenance to perform their best.

“Yesterday I was rushing to print contracts for a client meeting when my printer decided to have a paper jam party,” shared one of our Daytona Beach customers. “The culprit? Worn pickup rollers that hadn’t been cleaned in months.”

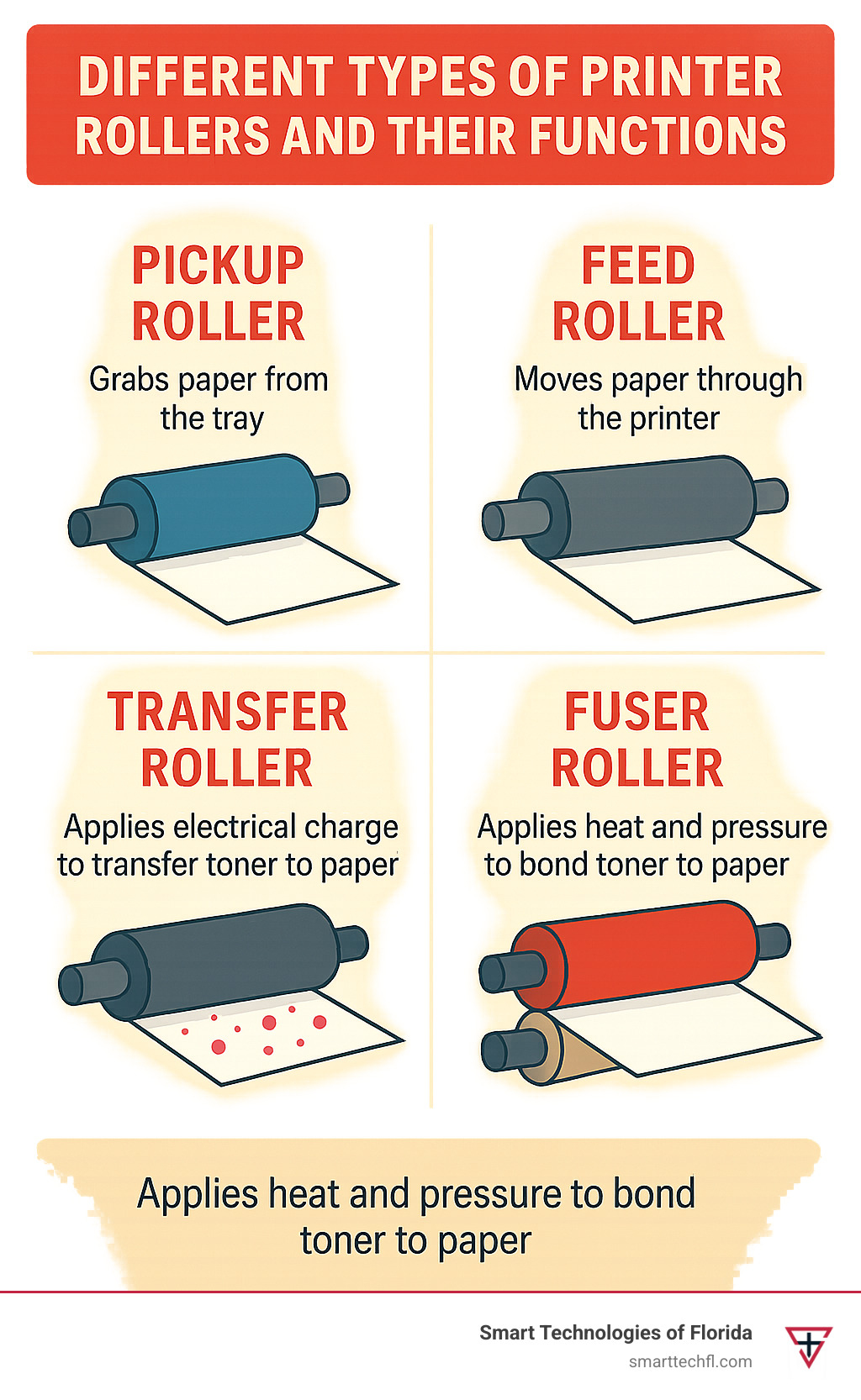

Your printer contains several different types of rollers, each with specific maintenance needs:

Pickup rollers grab paper from the tray and tend to wear out fastest. Give these a monthly cleaning with a lint-free cloth slightly dampened with isopropyl alcohol to prevent those frustrating no-feed errors.

Feed rollers move paper through the printer path. A quarterly cleaning using the same method as pickup rollers will keep paper moving smoothly.

Transfer rollers apply the electrical charge that helps toner stick to paper. These delicate components usually need replacement rather than cleaning after about 100,000 impressions.

Fuser rollers apply heat and pressure to bond toner permanently to paper. While they rarely need cleaning, they’re typically replaced during major maintenance intervals.

When it’s time to clean your rollers, follow this simple process: power off and unplug your printer, let it cool completely, then access the rollers according to your printer manual. Gently wipe with a lint-free cloth slightly dampened with 70% isopropyl alcohol, rotating each roller to clean the entire surface. Always allow them to dry completely before reassembling.

“Here in Florida’s humid climate, we see accelerated roller wear,” notes our senior technician. “The moisture causes paper to expand slightly, increasing friction during feeding. That’s why our local clients need more frequent roller maintenance than the national average.”

How do you know when cleaning isn’t enough? Watch for these signs that your rollers need replacement: visible wear lines or glazing on the rubber surface, cracks or splits, consistent paper jams even after cleaning, multiple sheets feeding simultaneously, or paper that consistently feeds at an angle.

Laser printer maintenance tips for rollers also include being mindful of your paper. Properly stored paper (kept dry and dust-free) puts less strain on your rollers, while poorly stored paper can accelerate wear. A simple paper “flex and fan” before loading the tray can reduce the work your pickup rollers need to do.

Remember: those tiny rubber components might seem insignificant, but they’re the literal wheels that keep your business documents rolling smoothly through your workday.

6. Use Quality Paper & Genuine Toner Only

Your printer is only as good as what you put into it. This might sound like a sales pitch, but after 23 years of helping Florida businesses maintain their printers, we’ve seen how proper supplies can make or break your printing experience.

Think of your printer like a high-performance car – it needs the right fuel to run properly. Using the correct paper weight specified in your printer manual ensures smooth feeding through all those rollers we just talked about. When paper is too light, it can cause multiple feeds; too heavy, and it might jam in the curves of your paper path.

“I saved $20 on paper last month, but spent $300 on repairs this week,” a local retail owner told us recently. This story repeats itself in offices across Daytona Beach every day.

Proper paper storage plays a huge role in preventing issues too. Keep your paper sealed in its original packaging until needed, and store it in a dry location. Florida’s humidity can cause paper to absorb moisture, leading to curling and feeding problems. Before loading a fresh ream, take a moment to flex, fan, and straighten the stack – this simple step separates sheets and reduces static that can cause jams.

When it comes to toner, the temptation to save money with third-party cartridges is strong. However, genuine OEM toner is manufactured specifically for your printer’s heating elements and internal components. Off-brand alternatives might seem economical upfront but often lead to streaky prints, premature wear on components, and even toner leakage that can damage internal parts.

Refilled cartridges are particularly problematic – we’ve seen countless drums damaged by inconsistent toner particles from refilled cartridges. The repair costs typically erase any savings you might have enjoyed initially.

Another mistake we often see is running the printer when toner is low. Your printer warns you about low toner for good reason – continuing to print can damage the imaging drum as it tries to transfer increasingly sparse toner to your pages. Replace those cartridges promptly when the warning appears.

At Smart Technologies of Florida, we’ve helped many businesses create a supplies management plan that actually reduces overall printing costs while maintaining quality. One client reduced their annual printer maintenance calls by 67% simply by switching to the correct paper weight and genuine toner.

For a deeper dive into best practices for printer supplies and overall maintenance strategies, check out our Printer Maintenance 101: Tips for Every Office.

What you save on cheap supplies today often becomes tomorrow’s repair bill. Quality in means quality out – and a printer that keeps running smoothly for years to come.

7. Run Utility Software & Stay Updated

Your laser printer isn’t just a mechanical device—it’s also a sophisticated piece of technology with built-in software that needs regular attention. Think of these digital tools as your printer’s way of telling you what it needs before problems become visible in your prints.

Most people don’t realize their printer comes with powerful diagnostic and maintenance utilities hiding in plain sight. These tools are your first line of defense against potential issues and can significantly extend your printer’s life.

“I’ve seen countless printers retired early simply because their owners never ran the built-in maintenance utilities,” shares our lead technician at Smart Technologies of Florida. “It’s like owning a car but never checking the oil!”

The cleaning page cycle is perhaps the most valuable utility in your printer’s digital toolkit. This simple process runs special high-toner pages through your printer that collect debris and excess toner particles from internal components. Make it a habit to run this monthly, or immediately when you notice print quality starting to decline.

For those with color laser printers, regular calibration is essential. Colors can drift over time or after replacing toner cartridges, leading to inconsistent output. The calibration utility ensures your blues stay blue and your reds stay red—critical for businesses that print marketing materials or presentations.

Don’t ignore your printer’s digital voice. The status report and error logs contain valuable insights about your printer’s health. Taking five minutes each month to review these can help you spot patterns—like recurring paper jams in a specific location—that might indicate a developing problem.

Firmware updates are the equivalent of vitamins for your printer. Manufacturers regularly release these updates to improve performance, fix bugs, and patch security vulnerabilities. In our increasingly connected world, an outdated printer can actually become a security risk for your entire network.

“We had a client whose accounting department printer was compromised because they hadn’t updated the firmware in three years,” recalls our cybersecurity specialist. “The hackers used it as an entry point to the network—all preventable with regular updates.”

For Brother printer owners, we’ve compiled specific guidance in our Brother Laser Printer Maintenance Tips: Essential Guide, which walks you through the unique utility menu structure of these popular business printers.

Digital laser printer maintenance tips for trouble-free operation

Make your printer work smarter, not harder, by establishing a weekly self-test routine. This simple diagnostic page can reveal subtle issues before they become major problems. Many of our clients in Daytona Beach set a reminder to run this test every Friday afternoon—it takes just seconds but provides valuable peace of mind.

Monitor your page counts like you would the mileage on your car. Most printer issues are predictable based on usage, not time. By keeping an eye on these numbers, you can anticipate when components might need attention and schedule maintenance before failure occurs.

If your printer supports email or mobile alerts (most modern networked printers do), enable these notifications to receive timely warnings about low supplies or developing issues. This feature has saved many of our clients from the frustration of finding an empty toner cartridge right before an important presentation.

At Smart Technologies of Florida, we’ve implemented automated monitoring systems for many businesses throughout Volusia County. These systems have reduced printer downtime by nearly 40% by alerting IT teams to potential issues before users even notice a problem. It’s a perfect example of how digital maintenance is just as important as physical cleaning in today’s connected office environment.

Your printer’s software is the brain behind the mechanical brawn—give it the regular attention it deserves, and it will serve you faithfully for years to come.

8. Watch Wear Parts & Replace on Time

Every laser printer has a collection of components that are designed to be replaced over time. Think of these as the “consumables” of your printer—just like the tires on your car, they’ll wear down with use no matter how well you maintain them.

“Replacing worn parts like the fuser, imaging drum, and rollers can restore print quality and extend a laser printer’s life up to 300,000 pages,” according to industry data. This proactive approach to maintenance can save you significant money in the long run.

The most common wear parts have predictable lifespans, though these vary by printer model and usage patterns. Your imaging drum typically lasts between 12,000-20,000 pages before needing replacement. The fuser assembly, which applies heat to bond toner to paper, generally soldiers on for about 100,000 pages. Your printer’s transfer roller or belt will typically handle 50,000-100,000 pages, while pickup and feed rollers often need replacement around the 50,000-page mark. Don’t forget about those humble separation pads that prevent multiple sheets from feeding—they typically need replacement after 30,000-50,000 pages.

Your printer will usually tell you when something’s not right. When your imaging drum is wearing out, you’ll notice streaks, spots, or ghost images appearing on your printed pages. A failing fuser assembly leaves you with wrinkled pages or toner that smears when touched (because it’s not properly bonded to the paper). If your transfer roller or belt is on its last legs, your prints will appear faded or have uneven toner application. Consistent paper jams or failure to feed paper properly often signal that your pickup or feed rollers need attention. And when you suddenly start getting multiple sheets feeding at once, your separation pads are likely the culprit.

“After about 100,000 prints, the fuser assembly may require replacement to maintain print quality,” notes a printer technician. This isn’t just about keeping your prints looking good—it’s about preventing more serious damage to your printer.

Many manufacturers make maintenance simpler by offering maintenance kits that include commonly replaced parts bundled together. These kits are designed for specific page-count intervals and can be more cost-effective than buying individual components. They’re like the “tune-up kits” for your printer.

For those using HP printers, our guide on HP Laser Printer Maintenance Tips: Keep Your Printer Running Smoothly provides model-specific guidance that can help you stay ahead of maintenance needs.

Here at Smart Technologies of Florida, we’ve found that businesses who keep a maintenance kit on hand for each printer model they heavily use experience far less downtime when components inevitably reach their end of life. It’s like keeping a spare tire in your trunk—you hope you won’t need it, but you’ll be glad it’s there when you do.

Replacing wear parts isn’t just about fixing problems—it’s about preventing them before they disrupt your workflow. A small investment in replacement parts can save you from the much larger cost of emergency repairs or premature printer replacement.

9. Create a Personalized Laser Printer Maintenance Tips Schedule

The secret to a long-lasting printer isn’t just knowing what maintenance to perform—it’s knowing when to perform it. Your printer’s needs vary dramatically based on how much you use it, and creating a personalized schedule can make all the difference.

“I’ve seen the same printer model last three years in one office and eight years in another,” shares one of our technicians at Smart Technologies of Florida. “The difference wasn’t luck—it was simply that one business had a maintenance schedule they actually followed.”

Understanding your printer’s duty cycle (the maximum number of pages it’s designed to print monthly) is the foundation of your maintenance plan. This number is usually listed in your printer’s specifications and serves as a guideline for how much work your printer can handle without excessive wear.

For home users printing less than 500 pages monthly, your schedule can be fairly relaxed. A weekly quick wipe-down of the exterior and a monthly more thorough cleaning should suffice. Quarterly, take time to inspect rollers and run utility software, with perhaps an annual deep cleaning or professional service.

Business users printing between 1,000-5,000 pages monthly need to be more vigilant. Daily visual inspections become important, with weekly exterior cleaning and paper path checks. Monthly, you’ll want to dust interior components, clean rollers, and run diagnostic software. Consider a professional quarterly service to keep everything running smoothly.

High-volume environments exceeding 5,000 pages monthly require the most attentive care. Daily inspections and cleaning become essential, with weekly interior maintenance. Professional servicing every quarter is strongly recommended, with comprehensive maintenance including replacement of wear parts twice yearly.

“Proper maintenance isn’t just about fixing problems—it’s about preventing them before they start,” notes our senior technician with over 20 years of experience. “A printer that’s well-maintained consistently produces better quality prints with fewer interruptions.”

Creating a simple maintenance log can work wonders for keeping track of your printer’s care. Include the date of service, what maintenance you performed, any parts you cleaned or replaced, the current page count, any issues you noticed, and when the next service is due. This documentation helps identify patterns and anticipate when components might need attention.

For more information about the costs associated with different maintenance approaches, check out our detailed guide on Laser Printer Maintenance Costs Explained.

Weekly & Monthly Laser Printer Maintenance Tips at a Glance

| Task | Home User (Weekly) | Home User (Monthly) | Business (Weekly) | Business (Monthly) |

|---|---|---|---|---|

| Exterior Cleaning | ✓ | ✓ | ✓ | ✓ |

| Paper Path Check | ✓ | ✓ | ✓ | |

| Toner Level Check | ✓ | ✓ | ✓ | |

| Roller Inspection | ✓ | ✓ | ||

| Roller Cleaning | ✓ | |||

| Run Cleaning Page | ✓ | ✓ | ✓ | |

| Interior Dusting | ✓ | |||

| Error Log Review | ✓ | |||

| Firmware Check | ✓ |

Here in Daytona Beach, we’ve noticed businesses often need to adjust their maintenance schedules to account for our humidity. Paper storage becomes especially important in our climate, and more frequent roller inspections can prevent the jams that occur when paper absorbs moisture from the air.

At Smart Technologies of Florida, we love helping local businesses develop custom maintenance plans custom to their specific equipment and usage patterns. We’ve found that these personalized approaches deliver much better results than one-size-fits-all recommendations. After all, your printer is as unique as your business—shouldn’t its care plan be too?

10. Know When to Call the Pros

Even the most dedicated DIY printer enthusiast reaches a point where professional help makes sense. While the laser printer maintenance tips we’ve covered will keep your printer running smoothly most of the time, recognizing when to bring in experts can save you money and headaches in the long run.

Professional maintenance isn’t just for emergencies—it’s a smart preventive measure. Industry standards suggest scheduling professional service at least annually for business printers, and quarterly if your printer handles heavy volumes or supports critical operations.

How do you know it’s time to make that call? Trust your instincts when you notice persistent quality issues that don’t improve despite your maintenance efforts. Unusual noises—grinding, squeaking, or thumping—often signal internal problems that require specialized attention. Those stubborn error codes that won’t clear with basic troubleshooting? That’s your printer’s way of asking for professional help.

“I had a client who spent three frustrating days trying to fix streaking on their prints,” shares one of our technicians. “Turns out, they needed a simple fuser replacement—a 30-minute job for us, but nearly impossible without the right tools and parts.”

Professional printer technicians bring several advantages to the table. They have specialized tools that aren’t available to consumers, access to genuine replacement parts, and perhaps most importantly, the training to safely disassemble and reassemble complex components without causing additional damage. They can also perform comprehensive electrical testing, sensor calibration, and firmware updates that might be beyond the scope of in-house maintenance.

For businesses, maintenance contracts often provide the best value. Think of these as “printer insurance”—regular scheduled maintenance prevents problems before they start, plus you’ll get priority response when issues do arise. Most contracts include discounted parts and labor, and some even provide loaner equipment during extended repairs so your operations never miss a beat.

When weighing whether to handle maintenance in-house or call in the pros, consider these factors:

Cost of downtime: What does it cost your business when the printer isn’t working? For many businesses, even a few hours of printer downtime can cost more than a service call.

Equipment value: More expensive printers usually justify more professional care to protect your investment.

Staff time: Is printer maintenance the best use of your team’s valuable time?

Risk assessment: Improper maintenance can sometimes cause more problems than it solves.

At Smart Technologies of Florida, we’ve developed flexible maintenance options for businesses throughout the Daytona Beach area. Our local clients particularly appreciate our quick response times—we understand that in Florida’s business climate, waiting days for printer service simply isn’t an option.

“Hiring a professional is like having an insurance policy for your printing operations,” notes our lead technician. “We don’t just fix problems—we prevent them from happening in the first place.”

For more information about professional service options that fit your business needs, explore our partner’s Maintenance contracts.

Frequently Asked Questions

How often should I clean my laser printer?

The right cleaning schedule really depends on how much you print and where your printer lives. In most office settings, we’ve found this rhythm works well:

- Exterior cleaning: Weekly

- Paper path inspection: Weekly

- Deep cleaning of accessible components: Monthly

- Professional cleaning of internal components: Annually

If your printer sits in a dusty warehouse or churns out more than 5,000 pages monthly, you’ll want to clean more frequently. On the flip side, home users who print occasionally can usually get away with monthly exterior wipes and quarterly peeks inside.

“The cleaning schedule isn’t one-size-fits-all,” explains our lead technician at Smart Technologies of Florida. “A busy retail store printing receipts all day needs more attention than a home office printing a few documents weekly.”

Which parts need regular replacement?

Your laser printer has several components that are designed to wear out and be replaced—think of them like the tires on your car. Here’s what to expect:

Your toner cartridges will need replacing when the printer indicates (typically every 2,000-10,000 pages depending on capacity). The imaging drum usually lasts 12,000-20,000 pages, though in some models it’s built into the toner cartridge.

For longer-term components, the fuser assembly typically needs replacement around the 100,000-page mark, while transfer rollers/belts generally last 50,000-100,000 pages. Your pickup and feed rollers will typically need replacing around 50,000 pages, and separation pads usually wear out after 30,000-50,000 pages.

Many printer manufacturers offer maintenance kits that bundle these wear parts together, making it easier to refresh multiple components at once when you hit certain page-count milestones.

Can using cheap toner really damage my printer?

Yes, bargain-bin toner cartridges can absolutely harm your printer, and we’ve seen the damage in many Daytona Beach businesses. While the initial savings might seem attractive, low-quality toner often creates expensive problems down the road.

Think of it this way: your printer was engineered to work with specific toner formulations. When you use low-quality alternatives, you might experience:

Leaking toner that makes a mess of internal components, toner with inconsistent particle sizes that produces spotty prints, and improper electrical charging that can damage the sensitive drum. We’ve also seen cheap toner with improper melting temperatures cause premature wear on the expensive fuser assembly, and leave behind residue that gums up other components.

“I once had a client who saved $200 using third-party toner over six months, then needed a $450 repair because that toner damaged their fuser,” shares one of our technicians. “Sometimes being penny-wise becomes pound-foolish.”

While genuine OEM cartridges do cost more upfront, they’re often more economical long-term because they reduce maintenance issues and help your printer live a longer, healthier life. Think of quality toner as preventive medicine for your printer—a small investment that prevents bigger expenses later.

Conclusion

Caring for your printer isn’t just about fixing problems—it’s about preventing them before they start. The laser printer maintenance tips we’ve shared throughout this guide represent your roadmap to printer longevity and reliable performance.

Think of your printer as you would your car—regular maintenance isn’t optional, it’s essential. That small investment of time spent cleaning rollers or running utility software pays enormous dividends by preventing costly repairs and frustrating downtime just when you need your printer most.

At Smart Technologies of Florida, we’ve seen how proper maintenance transforms printer reliability for our Daytona Beach clients. One local retail business implemented our quarterly maintenance schedule and reduced their printer-related disruptions by nearly 70% in the first year alone. Their staff no longer dreads printing large batches of invoices at month-end!

Maintenance needs vary based on your specific situation. A busy medical office printing hundreds of documents daily will need more frequent attention than a home-based business with occasional printing needs. The principles remain the same, but adjust your schedule accordingly.

Our team brings 23 years of experience helping businesses steer technology challenges with a distinctly human touch. We understand that behind every printer is a person trying to get their work done, and our people-centric approach means we’re focused on your success, not just your equipment.

When maintenance feels overwhelming or you encounter issues beyond your comfort level, that’s when professional help makes sense. There’s no shame in calling in experts—in fact, it’s often the most cost-effective solution for complex problems.

Whether you’re maintaining a single desktop printer or managing a fleet across multiple locations, we’re here to help when you need us. Our approach is never “one-size-fits-all”—we take the time to understand your specific needs and develop solutions custom to your business goals.

For more information about how Smart Technologies of Florida can support your printing needs and other business technology requirements, visit our More info about printers & copiers page.

By implementing these maintenance practices and partnering with the right technology provider, your laser printer can remain a reliable workhorse for your business for years to come—delivering crisp, professional documents whenever you need them.