Mastering the Art of Printer Ink Tank Refills

Printer ink tank refill systems are changing how businesses approach printing costs and environmental responsibility. Instead of replacing expensive cartridges every few weeks, you simply refill built-in tanks with affordable ink bottles.

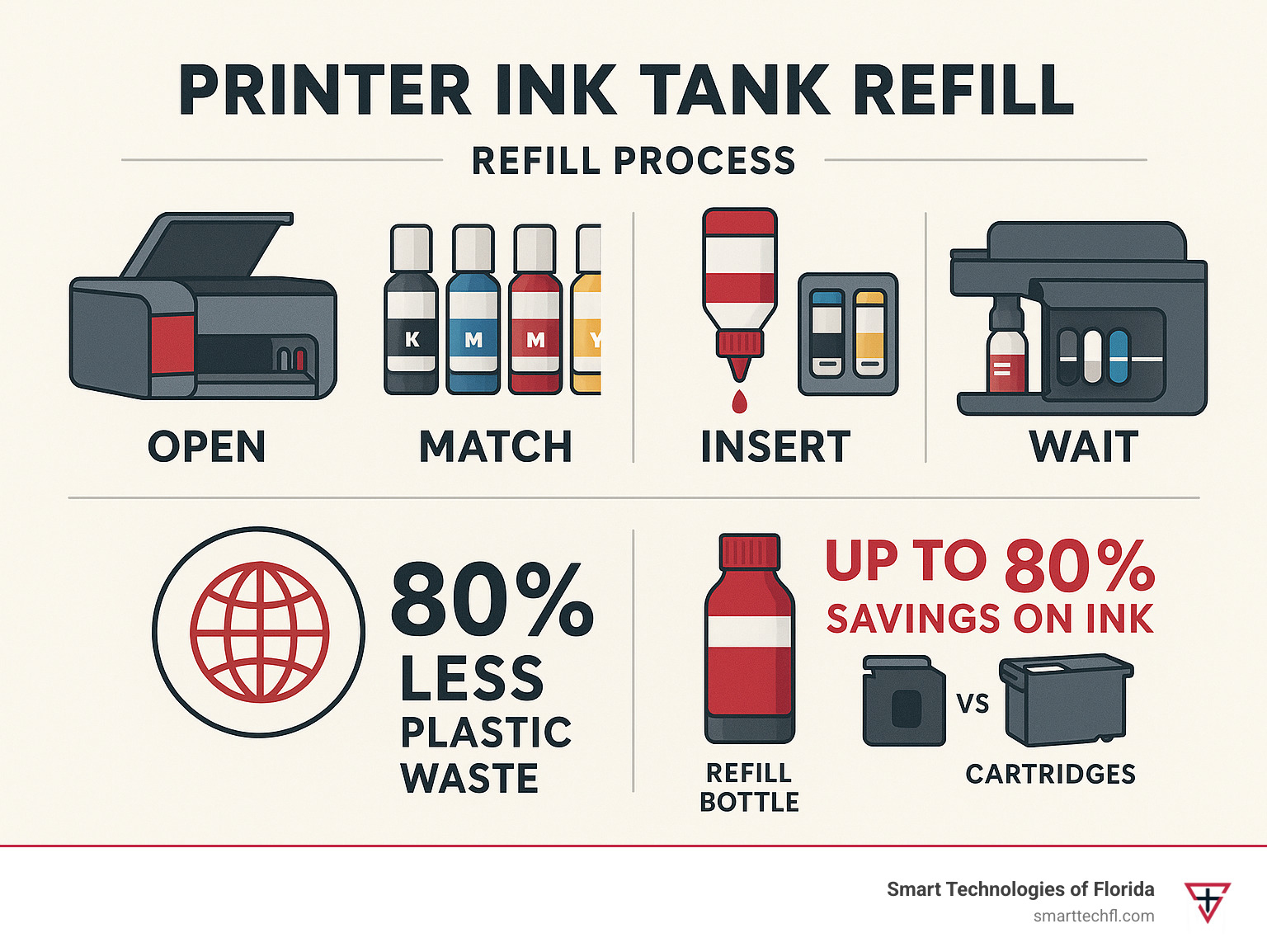

Quick Answer for Printer Ink Tank Refill:

- Open the ink tank cover on your printer

- Match ink bottle color to tank label (bottles are keyed to prevent errors)

- Insert bottle upright into filling port – ink flows automatically

- Wait for auto-stop when tank reaches fill line

- Close tank cap and cover – ready to print

The numbers tell the story. Epson EcoTank printers can save users up to 80% on ink costs compared to traditional cartridges. A typical refill costs just $10-20 versus $50-75 for new cartridges.

For retail businesses struggling with high operational costs, this represents real savings. One mid-sized store reported cutting their monthly printing expenses from $300 to $60 after switching to refillable tanks.

The environmental impact matters too. Millions of EcoTank users have prevented millions of pounds of plastic cartridge waste from reaching landfills. Each refill bottle replaces multiple cartridges over its lifetime.

The process itself is surprisingly simple. Modern ink tank systems use gravity-fed design with automatic stop mechanisms. Bottles are color-coded and keyed to prevent mixing colors. Most refills take under 5 minutes with minimal mess.

Ink Tank Printers vs. Cartridge Printers: What You Need to Know

Picture this: you’re in the middle of printing an important presentation when your printer stops dead. “Replace cartridge” flashes on the screen. You’ve got two choices – rush to the store for a $50 cartridge or wish you’d chosen an ink tank printer instead.

The difference between these two systems is like comparing a gas-guzzling car to a fuel-efficient hybrid. Traditional cartridge printers are the gas guzzlers of the printing world. They store ink in removable plastic containers that snap into your printer. When they’re empty, you toss the whole thing – plastic housing, electronics, sometimes even the print head.

Ink tank printers take a smarter approach. They have built-in reservoirs that you simply refill with ink bottles. The print head stays put, connected to the tanks through tubes or direct contact. No more throwing away perfectly good plastic every few weeks.

Here’s where it gets interesting. A typical ink cartridge gives you 200-300 pages and costs $20-60. That works out to roughly 10-20 cents per page. Ink tank systems? They can hit costs as low as 0.3 cents per page for black text and 0.9 cents for color printing.

| Feature | Cartridge Printers | Ink Tank Printers |

|---|---|---|

| Cost per black page | 10-20 cents | 0.3-1 cent |

| Cost per color page | 15-25 cents | 0.9-2 cents |

| Refill frequency | Monthly | Quarterly or less |

| Plastic waste | High (entire cartridge) | Minimal (bottles only) |

| Page yield per refill | 200-300 pages | 4,000-7,500 pages |

How Ink Tank Systems Work

Think of ink tank systems like a well-designed plumbing system for your printer. Capillary action and gravity work together to move ink from the reservoirs to where it’s needed. When your printer wants to put ink on paper, it simply draws from these tanks through sealed tubes or direct contact points.

Airtight seals keep everything fresh and prevent messy leaks. Most systems use rubber gaskets and threaded caps to maintain just the right pressure. The tanks themselves are see-through, so you can easily check your ink levels without any guesswork.

The real genius is in the keyed bottles. Each ink bottle has a unique shape that only fits its matching tank. Try to put cyan ink in the magenta tank? It simply won’t fit. This foolproof design means you can printer ink tank refill your system without worrying about color mix-ups.

Why the Design Matters for Printer Ink Tank Refill Efficiency

The continuous ink supply design means your printer rarely has to take a coffee break. Instead of stopping mid-job because a cartridge ran dry, you can print thousands of pages before needing a refill. This consistency is a game-changer for busy offices.

Fewer replacements translate to less downtime and frustration. Many businesses report cutting their printer maintenance time by 70% after switching to tank systems. Instead of monthly cartridge hunting trips, they handle printer ink tank refill tasks quarterly or even less often.

This efficiency matters more than you might think. When your printer runs smoothly, your team stays productive. When it’s constantly demanding new cartridges, it becomes that office equipment everyone loves to complain about.

Why Refill? Savings, Sustainability & Performance Gains

Let’s talk numbers first, because that’s what most business owners want to hear. The total cost of ownership (TCO) for ink tank printers tells a compelling story once you look beyond the initial sticker price. You might pay more upfront for the printer itself, but those 80% savings on ink costs start adding up fast.

Picture this: your office prints about 500 pages monthly. With traditional cartridges, you’re probably spending around $250 annually on ink. Switch to a printer ink tank refill system, and that number drops to about $50. That’s $200 back in your pocket every year – money you can invest in growing your business instead of feeding the ink monster.

But here’s where it gets interesting. We’re not just talking about your bottom line. Every year, over a billion inkjet cartridges end up in landfills across the globe. Each one contains plastic, metal components, and residual ink that’ll still be sitting there long after we’re gone. Landfill reduction isn’t just feel-good marketing speak – it’s a real environmental crisis that refillable tanks help solve.

The ink itself offers some interesting choices too. Pigment inks resist fading and water damage, making them perfect for important documents and photos you need to keep. Dye inks deliver those vibrant, eye-catching colors that make your marketing materials pop. Most tank systems give you the flexibility to choose what works best for your specific needs.

Real-World Cost Breakdown

Here’s where the math gets really exciting. Those bulk bottles are game-changers when you break down the actual cost per milliliter. A typical 70ml ink bottle costs about $15 and can replace three or four cartridges that would normally cost you $150 total.

We’re talking about dropping from $2-3 per milliliter with cartridges down to just $0.20-0.30 per milliliter with bottles. That’s not just savings – that’s a complete change of your printing economics.

And here’s a bonus many businesses don’t consider: subscription avoidance. You know those recurring ink delivery services that seem convenient at first? They’re designed to lock you into regular payments whether you need ink or not. Tank systems let you buy ink on your schedule, often in bulk when you find good deals.

Environmental Upside of Printer Ink Tank Refill

The environmental benefits go deeper than just avoiding cartridge waste. When you reuse the same tank system over and over, your printer actually lasts longer. Think about it – you’re not constantly jamming cartridges in and out, wearing down those delicate mechanical parts. Less wear means your printer keeps running smoothly for years longer.

The carbon footprint reduction is significant too. One ink bottle replaces multiple cartridges, which means less manufacturing, less packaging, and fewer delivery trucks burning fuel to bring you supplies. Over your printer’s lifetime, that environmental impact really adds up.

But the biggest win? Zero cartridge waste. Not reduced waste, not recyclable waste – zero waste. If your business is working toward sustainability goals or environmental certifications, this alone can make a meaningful difference in your impact reports.

Pros & Cons of Using Third-Party Ink

Let’s be honest about the potential downsides, because no solution is perfect. Warranty concerns top most people’s worry list. Some manufacturers claim third-party inks void warranties, though this practice faces increasing legal challenges. Our advice? Check your specific warranty terms before making the switch, and keep your documentation handy.

Color gamut differences might matter if you do a lot of photo printing. Original manufacturer inks undergo extensive testing to match printer specifications exactly. Third-party inks might produce slightly different colors, though quality suppliers work hard to minimize these differences. For most business printing, you probably won’t notice.

Chip recognition issues pop up occasionally with third-party inks. Some printers use chips to verify ink authenticity, but here’s the good news – most tank systems don’t rely on these chips anyway. This makes chip recognition much less of a concern than with traditional cartridge printers.

The key is finding the right balance for your specific needs. For more detailed guidance on making these decisions, check out Amazon’s sustainability data to see how major companies approach these choices.

Choosing the Right Refill Kit & Supplies

Getting the right supplies for your printer ink tank refill project starts with understanding your specific printer model. Think of it like buying the right oil for your car – close isn’t good enough when it comes to ink chemistry.

Compatibility charts become your best friend here. Each printer manufacturer designs their tanks for specific ink formulations. What works perfectly in your Epson EcoTank might damage an HP Smart Tank system. The good news? Most reputable ink suppliers provide detailed compatibility charts that take the guesswork out of shopping.

Bottle codes might look like random numbers, but they’re actually your roadmap to the right ink. Epson uses codes like T502 for their newer EcoTank models, while Canon goes with GT52 series for their MegaTank printers. The 552 series bottles serve Epson’s photo-focused printers that need extra colors for stunning prints.

Here’s where tank systems shine over traditional cartridges: chipless bottles eliminate the electronic headaches that plague cartridge refills. No worrying about chip recognition or compatibility issues – just pure, straightforward ink delivery.

The pigment versus dye decision depends on what you’re printing. Need documents that won’t fade or run if they get wet? Pigment inks are your answer. Want vibrant marketing materials that pop off the page? Dye inks deliver those rich, saturated colors that grab attention.

Syringe versus vacuum filling methods offer different trade-offs. Syringes give you precise control – perfect for careful, measured refills. Vacuum systems cost more upfront but make the job faster and cleaner. For busy offices, the time savings often justify the extra investment.

For more detailed guidance on cartridge refilling techniques, check out our ink cartridge refilling guide.

Decoding Model Numbers and Bottle Colors

Understanding bottle codes saves you from expensive mistakes and frustrated returns. T502 series bottles work with newer Epson EcoTank models like the ET-2800 and ET-4800 series. These bottles might look smaller than older versions, but they pack more concentrated ink formulations.

GT52 series bottles serve Canon MegaTank printers including popular models like the G3260 and G4270. Canon designed these bottles with unique threading that prevents you from accidentally mixing colors – a thoughtful touch that prevents costly mistakes.

552 series bottles cater to Epson’s photo-oriented EcoTank printers like the ET-8550. These systems often include additional colors like light cyan and light magenta that create smoother color transitions in photos. The extra colors mean more bottles to track, but the photo quality improvement is worth it.

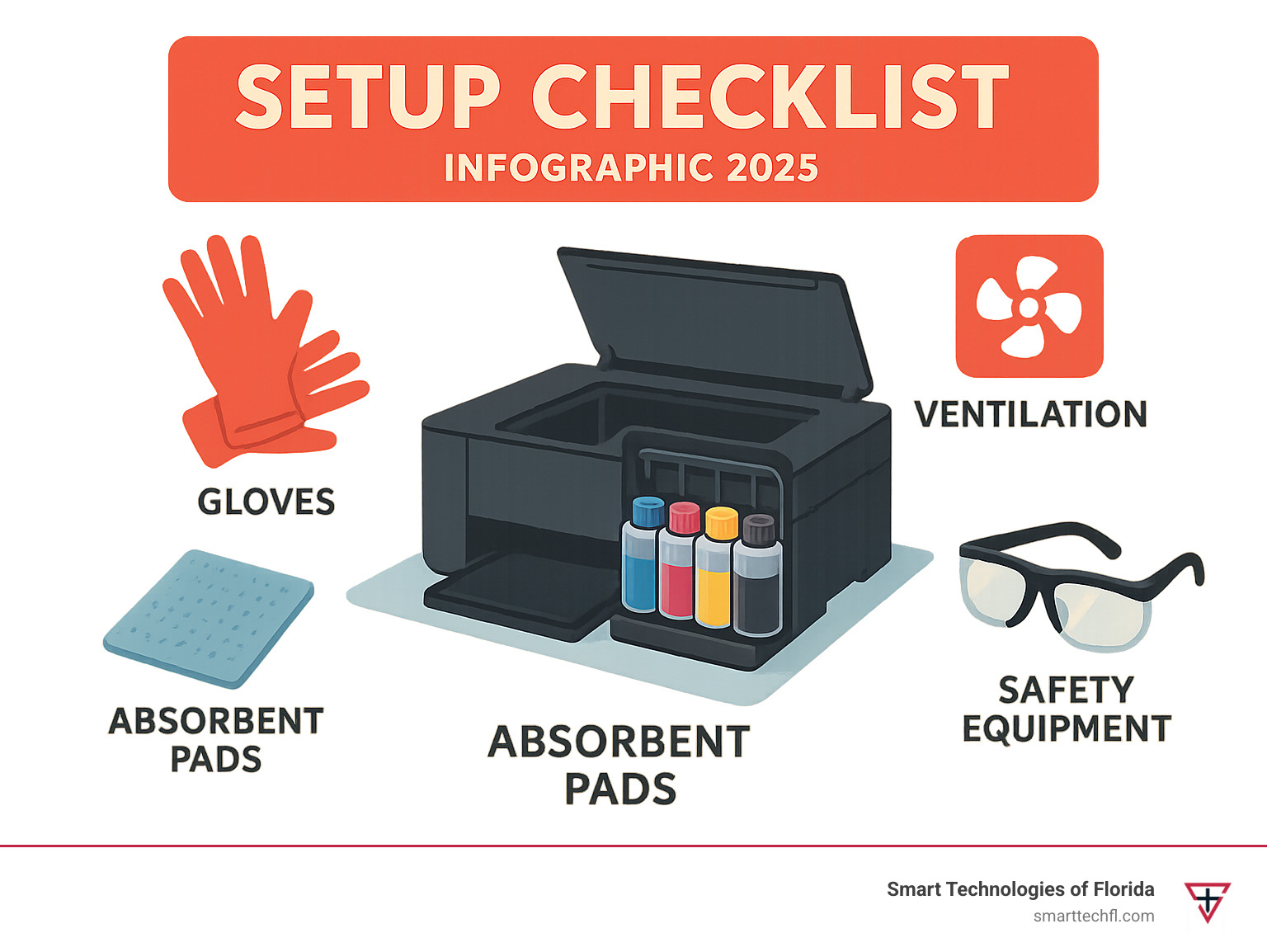

Safety Gear & Workspace Prep List

Printer ink tank refill projects go much smoother with proper preparation. Think of it as setting up for a small art project – a little prep work prevents big cleanup headaches later.

Nitrile gloves protect your hands from staining and potential irritation. Ink stains on your fingers make for good conversation starters, but they’re not exactly professional looking. Nitrile offers better chemical resistance than latex, though either works fine for occasional refills.

Absorbent pads catch those inevitable drips and spills. Place them under your work area before you start, not after you’ve already made a mess. Paper towels work in a pinch, but dedicated spill pads absorb more liquid and prevent ink from spreading across your workspace.

Lint-free cloths help clean up without leaving behind fibers that could clog your printer later. Regular paper towels or tissues might seem convenient, but they shed particles that cause problems. Microfiber cloths or dedicated printer cleaning wipes invest a few extra dollars in preventing bigger headaches.

Eye protection might seem like overkill for a simple refill, but ink splashes happen when you least expect them. Safety glasses provide the best protection, though even your regular reading glasses offer some defense against accidental splashes.

Step-by-Step Printer Ink Tank Refill Guide

Let’s walk through the actual printer ink tank refill process together. While each manufacturer has slight variations, the core principles remain refreshingly simple. Modern ink tank systems are designed with everyday users in mind – no engineering degree required.

The beauty of these systems lies in their gravity-fed design. You’re not fighting against complicated mechanisms or worrying about precise measurements. The tanks know when they’re full and stop accepting ink automatically. It’s like having a smart assistant that prevents you from making costly mistakes.

Printer Ink Tank Refill Preparation Checklist

Before you touch a single ink bottle, take a moment to set yourself up for success. Power off your printer completely – not just sleep mode, but fully off. This prevents any surprise print jobs from starting mid-refill and keeps electrical components safe from potential spills.

Slip on those gloves before handling anything. Even the most washable inks can leave your hands looking like you’ve been finger painting. Nitrile gloves give you the best grip and protection, though any disposable gloves work fine.

Open a window or turn on a fan for good ventilation. Modern inks aren’t dangerous, but fresh air makes the whole process more comfortable. Plus, if you do have a small spill, good airflow helps everything dry faster.

Printer Ink Tank Refill Procedure: Epson EcoTank

Epson has really thought this through. Align your ink bottle with the matching tank color – the bottles are cleverly designed so they only fit where they belong. It’s like a puzzle piece that prevents you from putting cyan ink in the magenta tank.

Here’s the part that surprises most people: don’t squeeze the bottle. Seriously. The system works by gravity and pressure equalization. Squeezing can actually cause problems like overflow or air bubbles that affect your print quality later.

Watch for the auto-stop mechanism to kick in. When ink reaches the proper level, it simply stops flowing. This happens because the air pressure equalizes – it’s actually pretty clever engineering wrapped in a simple design.

Close the cap snugly when you’re done, but don’t overtighten. Hand-tight creates the airtight seal needed to keep your ink fresh. Think of it like closing a jar of jam – firm but not forced.

Printer Ink Tank Refill Procedure: HP Smart Tank

HP takes a slightly different approach with their Smart Tank systems. Pop off the rubber plug carefully from the tank opening. These little rubber stoppers do the same job as threaded caps – just keep them clean and don’t lose them.

Pour slowly and steadily rather than dumping the ink quickly. HP tanks don’t have the same automatic stop feature as Epson systems, so you need to watch the fill level yourself. Think of it like pouring pancake batter – steady and controlled works best.

Replace the rubber plug firmly, making sure it sits flush with the tank opening. A proper seal keeps air out and maintains the consistent ink flow your printer needs for quality prints.

Some HP models need a priming cycle after refilling. Check your printer manual – if yours requires this step, it’s usually just pressing a button combination or running a menu option.

Avoiding Spills, Stains & Air Bubbles During Printer Ink Tank Refill

Keep your hands steady and take your time. There’s no prize for speed here, and rushing leads to the kind of mistakes that turn a simple refill into a cleanup project. If you’re feeling shaky or hurried, take a break and come back when you’re more settled.

Tilt your work surface slightly toward the tanks. This simple trick helps any minor spills flow away from electrical components. A small towel under the printer tray provides extra insurance against damage.

Run purge cycles after major refills to eliminate air bubbles. Most printers have built-in cleaning cycles that push air through the system. These cycles are your friend – use them liberally after refilling.

Post-Refill Initialization & Test Prints

Don’t declare victory just yet. Print a nozzle check pattern to verify that all colors are flowing correctly. Missing lines or gaps indicate clogs or air bubbles that need attention.

If your nozzle check shows problems, run a head cleaning cycle. This pushes fresh ink through the system and clears minor blockages. Most issues resolve after one or two cleaning cycles.

Some printers require color alignment after refilling. This process calibrates the print head position for optimal quality. It’s usually automatic, but check your printer’s menu system if colors seem off in your first few prints.

The whole process typically takes less than ten minutes, and you’ll be printing thousands of pages before you need to refill again. Not bad for a few minutes of work that saves you hundreds of dollars in cartridge costs.

Maintenance, Troubleshooting & Long-Term Care

Taking care of your printer ink tank refill system isn’t complicated, but it does require some attention. Think of it like maintaining a car – a little regular care prevents bigger problems down the road.

Clog prevention really comes down to one simple rule: use your printer regularly. Ink is like paint – it dries out when it sits too long. We recommend printing at least one page every week, even if it’s just a test page. This keeps the ink flowing and prevents those annoying dried-up print heads that can ruin your day.

Firmware messages can be a bit dramatic after you refill your tanks. Your printer might flash warnings about “non-genuine ink” or similar scary-sounding alerts. Don’t panic – these are usually just manufacturer warnings trying to discourage you from saving money. Most of the time, you can simply press “OK” or “Continue” and get back to printing.

Print-head cleaning becomes your best friend with tank systems. Unlike cartridge printers where you throw away the print head with each cartridge, tank systems keep the same print head for years. Running the automated cleaning cycle monthly helps maintain crisp, clear prints. Your printer’s menu system will guide you through this process.

Refill indicators work differently depending on your printer model. Some show actual ink levels on the screen, while others rely on transparent tanks that let you see the ink level directly. Either way, keeping an eye on these levels prevents the dreaded “empty tank in the middle of an important print job” scenario.

Knowing When It’s Time to Refill Your Ink Tank

Low-ink sensor warnings deserve your attention, even if they seem premature. These alerts typically appear when tanks are about 10-20% full, giving you time to order replacement ink before running completely dry. Ignoring these warnings can lead to print head damage or air bubbles in the system.

Faded colors tell their own story. If your photos start looking washed out or your text appears lighter than usual, check the corresponding ink levels. Often, one color runs low before others, especially if you print lots of photos or colorful documents.

Banding shows up as horizontal lines or streaks across your prints. This telltale sign usually means your ink levels are critically low. The print head can’t maintain consistent coverage, creating those annoying gaps in your documents or photos.

Troubleshooting After a Printer Ink Tank Refill

Question marks appearing on your printer display after refilling are more common than you might think. These symbols typically mean your printer can’t accurately read the new ink levels. The good news? Your printer will usually keep working normally despite these cryptic messages.

Airlocks can sneak into your system during refilling, especially if you’re in a hurry. These air bubbles block proper ink flow, making your prints look faded or patchy. The solution is usually simple – run a few cleaning cycles to push the air through the system.

Purge command options exist in most printer service menus for stubborn air bubble problems. However, we recommend sticking with the standard cleaning cycles unless you’re comfortable navigating technical menus. Most airlock issues resolve themselves with patience and a couple of cleaning cycles.

For more detailed troubleshooting strategies, check out our comprehensive printer ink toner refill guide.

How Many Refills Before Parts Wear Out?

10-15 cycles represent the typical lifespan for most tank system components. The tanks themselves are pretty durable, but the rubber seals and gaskets that keep everything airtight do wear out over time. Most users get several years of reliable service before needing any replacements.

Gasket wear usually announces itself through small leaks or tanks that won’t hold proper pressure. If you notice ink seeping around tank caps or the system seems to lose prime frequently, it might be time for new gaskets. The good news is that this repair is usually straightforward and inexpensive.

Tank replacement tips become relevant when your system has given you years of faithful service. Some manufacturers sell replacement tank assemblies, which can breathe new life into an older printer. However, if your printer is more than five years old, it might make more financial sense to upgrade to a newer model with improved features and efficiency.

The bottom line? With proper care and regular use, your printer ink tank refill system should provide years of reliable, economical printing. A little attention goes a long way toward keeping those ink costs low and your prints looking great.

Frequently Asked Questions about Printer Ink Tank Refill

Does using third-party ink void my warranty?

Here’s the good news: manufacturers legally cannot void your entire warranty just because you chose third-party ink. The Magnuson-Moss Warranty Act protects consumers from this practice. However, there’s a catch worth knowing about.

If third-party ink actually damages your printer, the manufacturer can deny warranty claims related to that specific damage. Think of it like using aftermarket oil in your car – the warranty remains valid unless that oil causes engine problems.

We’ve seen this play out with our clients over the years. High-quality third-party inks from reputable suppliers rarely cause issues. The key is choosing suppliers who test their formulations thoroughly and stand behind their products.

Most printer ink tank refill systems are actually more forgiving than cartridge printers when it comes to third-party inks. The tanks don’t rely on electronic chips or complex authentication systems that can reject non-OEM products.

How do I remove stubborn ink stains from hands or desks?

Nobody’s perfect – we’ve all been there with ink-stained fingers after a refill session. The trick is acting fast and using the right approach for different surfaces.

For skin stains, start with what you likely have handy. Rubbing alcohol or hand sanitizer breaks down most ink formulations quickly. Just dab some on a cloth and rub gently. If that doesn’t work, try dish soap with warm water – the degreasing agents help lift stubborn stains.

For furniture or desk stains, speed matters most. Grab a damp cloth immediately and blot (don’t rub) the stain. Rubbing can push ink deeper into porous surfaces. For hard surfaces like plastic or metal, mild soap and water usually do the trick.

Here’s a pro tip from our experience: avoid harsh chemicals like bleach or acetone on furniture. They might remove the ink but could also damage finishes or create discoloration that’s worse than the original stain.

What if my printer doesn’t recognize the refill?

This question comes up less often with tank systems than cartridge printers, but it still happens occasionally. The good news is that most tank systems don’t rely on the electronic recognition systems that cause headaches with cartridge printers.

Most tank systems use visual or mechanical indicators rather than electronic chips. Your printer tracks ink levels through sensors or simply relies on you to monitor the transparent tanks visually.

If you’re getting error messages after a printer ink tank refill, try these steps in order. First, run a cleaning cycle through your printer’s maintenance menu. This often resolves communication issues between the tanks and print heads.

Next, check that all tank covers are seated properly. Sometimes a slightly loose cover can trigger error messages. Remove and reseat each cover, making sure they click into place securely.

Persistent issues might require a printer reset or firmware update. Check your printer manufacturer’s website for the latest firmware version. Sometimes updates improve compatibility with refill procedures.

If none of these steps work, the issue might be with the ink itself rather than recognition problems. Try running a nozzle check to see if ink is flowing properly through all colors.

Conclusion

Mastering printer ink tank refill techniques transforms your printing economics and environmental impact. The 80% cost savings we’ve discussed aren’t just theoretical – they represent real money staying in your business account instead of flowing to ink cartridge manufacturers.

The environmental benefits compound over time. Every refill bottle you use instead of multiple cartridges reduces plastic waste and manufacturing emissions. For businesses pursuing sustainability goals, this represents measurable progress toward environmental responsibility.

At Smart Technologies of Florida, we understand that operational efficiency extends beyond digital change to everyday business processes. Our 23 years of experience helping businesses optimize their operations includes guidance on cost-effective printing solutions that align with your unique goals.

The techniques we’ve covered – from proper bottle alignment to troubleshooting post-refill issues – become second nature with practice. Start with our preparation checklist, follow the step-by-step procedures for your specific printer model, and don’t hesitate to run cleaning cycles when needed.

Printer ink tank refill mastery isn’t just about saving money today. It’s about building sustainable business practices that reduce costs and environmental impact over time. Every successful refill represents money saved and waste avoided.

Ready to optimize more aspects of your business operations? Our team specializes in identifying opportunities for efficiency improvements and cost reduction across all business processes. From our Daytona Beach location, we’ve helped countless organizations transform their operations for better performance and profitability.

Master your next refill, track your savings, and keep innovating. For additional insights into maximizing your printing cost savings, explore our comprehensive guide on printer cartridge refill benefits & cost.

Your journey toward printing cost mastery starts with that first successful refill. The techniques are simple, the savings are substantial, and the environmental benefits are lasting. Take control of your printing costs today.